The CMP-250 is a castable vacuum chamber for cold mounting. It can significantly improve penetration of voids and provide better edge retention. This machine is designed for impregnation of porous materials, such as specimens for failure analysis with cracks, porous casts, electronic components, rocks minerals, ceramics, etc. Its large vacuum chamber allows for 11 1.5inch molds to be processed simultaneously.

◆ Large vacuum chamber;

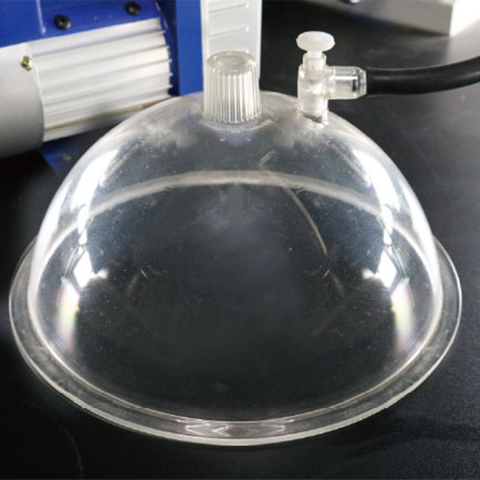

◆ Transparent cover, easy to observe samples;

◆ Retractable arm, easy to use;

◆ Efficient vacuum pump;

◆ Applications: epoxies resins, acrylic resins, Polyester resin, etc.

Description | CMP-250 |

Ultimate Vacuum | 10Pa |

Mold size | ● 30mm ○ 1,1.25,1.5, 2.0inch○Rectangular |

Power | 110/220V,50/60Hz, Single Phase |

Chamber (WxDxH) | 300*300*300 |

Pump(WxDxH) | 260*110*240 |

Weight | 6Kg |

Epoxies resins | ● 1sets |

Mould Release | ○ 250ml |

Transparent resin observation cover

High-efficiency vacuum pump

Gating System

Insert hard mould silicone soft film

Epoxy Set

Acrylic Suit

1

Copyright © 2018 Sinowon Innovation Metrology Manufacture Limited. | All Rights Reserved 粤ICP备16062806号

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.