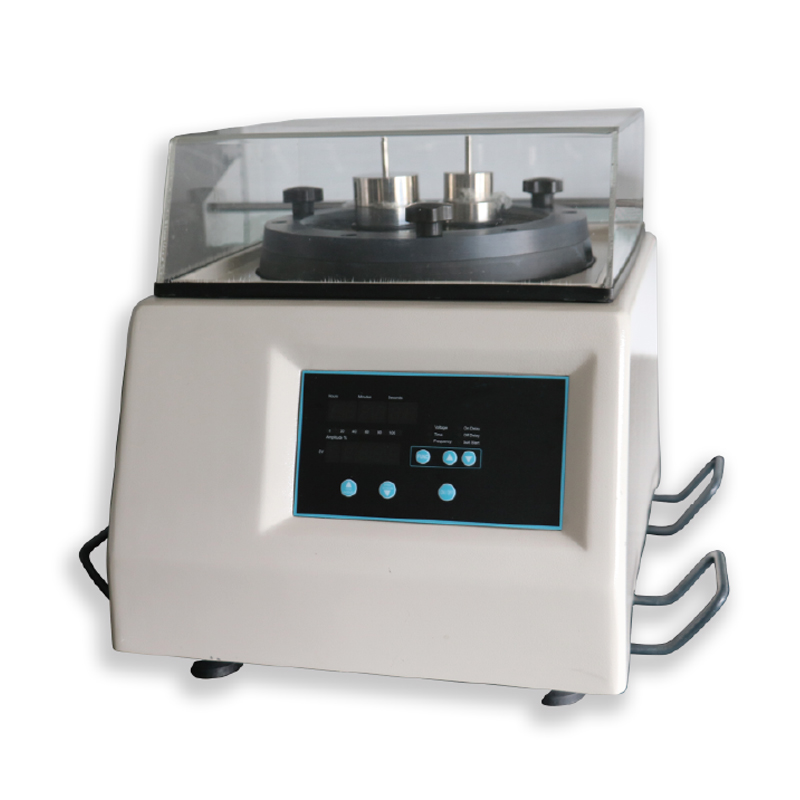

The GP-9 is an automatic vibratory polisher designed to prepare high quality polished surfaces on a wide variety of materials, especially for electron-backscatter diffraction (EBSD) applications. The high frequency vibration in horizontal motion produces a very effective polishing action to remove minor deformation remaining after mechanical preparation and reveal the stress-free surface. Ideal for EBSD specimens preparation.

◆ Frequency and voltage controls. By adjusting the vibrating frequency, different size specimens can be polished. By changing the applied voltage,the speed of the polishing action can be easily controlled;

◆ Timer control. Stop automatically;

◆ Capable of handling small or large specimens;

◆ Multiple size holders (1-inch upto 2-inch diameter, others can be customized);

◆ Robust and durable design;

◆ Easy to use and service;

◆ Ideal for all materials.

Description | GP-9 |

Bowl Size (mm) | Ø228.6mm/9inch |

Power | 110/220V,50/60Hz |

Motor | 350W |

Dimension(WxDxH) | 430*530*440 |

Weight(kg) | 82 |

Specimen Holder, 1.25inch | ● 3pcs |

Holder Weights, 1.25inch | ● 3pcs |

Lever Plate for 1.25inch | ● 1pcs |

Polishing Pad | ● 1pcs |

Other holders, weights and lever plate | ○ 1inch ○ 1.5inch ○ 2inch,can be customized |

●Standard○Option

Copyright © 2018 Sinowon Innovation Metrology Manufacture Limited. | All Rights Reserved 粤ICP备16062806号

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.