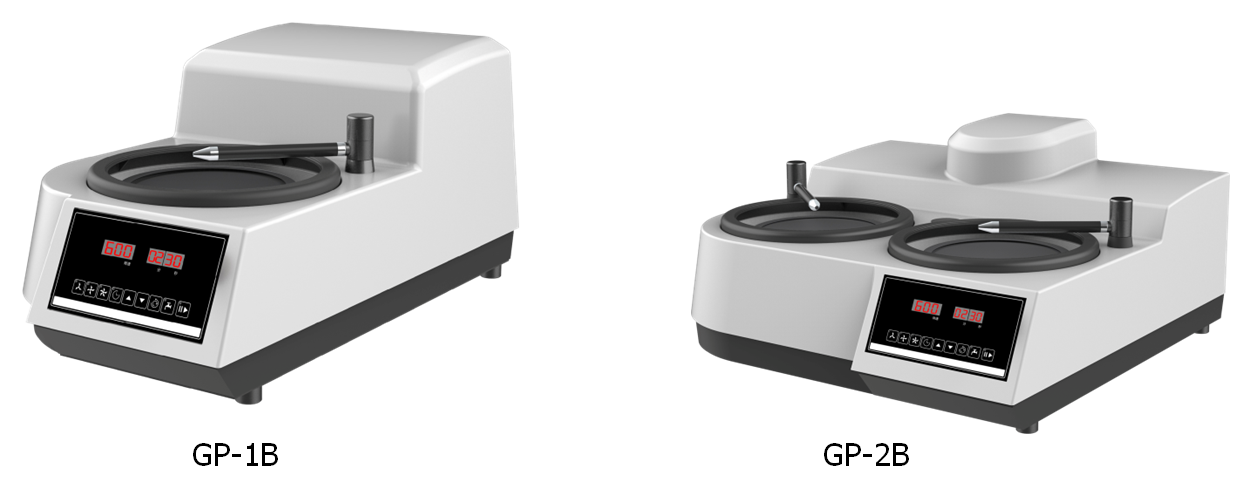

GP-1B/GP-2B are grinder and polisher for metallographic specimen preparation. The strong and variable speed drive allows application for all working steps.

◆ Simple operation for grinding and polishing;

◆ Variable speed. Preset three fast speed buttons;

◆ CCW and CW direction control;

◆ The water hose with universal direction can be pulled out for cleaning the basin;

◆ Plastic disposable bowl liner for ease of cleaning;

◆ Hard anodized aluminum working wheel;

◆ Durable composite construction, antirust;

◆ Powder coated aluminum housing, durable and reliable.

Description | GP-1B | GP-2B |

Wheel (mm) | ●Ø203○Ø254 | |

Speed(rpm) | 100-1000 | |

Motor | 550W | |

Power | 110/220V | |

Paper Ring | ● | ● |

Splash guard | ● | ● |

Cover | ● | ● |

Grinding paper | ● | ● |

Polishing Cloth | ● | ● |

Diamond Spray | ○ | ○ |

Diamond Slurry | ○ | ○ |

Alumina Powder | ○ | ○ |

Recirculating Tank | ○ | ○ |

●Standard○Option

Copyright © 2018 Sinowon Innovation Metrology Manufacture Limited. | All Rights Reserved 粤ICP备16062806号

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.