1. Application of Linear Scales

SG series of Linear Scales are widely used with Sinowon profile projectors, toolmaker microscopes, video measuring machines etc. SG Linear scale has good dynamic performance, great moving speed, and perfect reliability, not only can they meet the requirements of normal shaft dynamic performance, but also the requirements of direct drive equipment of highly dynamic performance.

2. Features of Linear Scales

l It adopts the advanced coating replication technology of glass grating, which ensures the accuracy of glass pitch, the benchmarks of main and auxiliary grating.

l It adopts the imported electronic components and uses the latest STM chip mounting technology that ensures the durability of electronic components for each linear encoder.

l Scan read system adopts the reliable and durable five-bearing design, it ensures the movement of optical induction system smoothly and durably.

l It adopts the double anti-oil, high elasticity and anti-aging plastic as dust-seal, it ensures optimum sealing performance and minimal friction force.

l It adopts the positioning spring as position controller for the scan read, it ensures the movement of bearing pulley durably and smoothly even in the condition of high-speed.

l It is strictly inspected by testing instrument for each glass, electronic components, dust-seal and snake skin tube, it ensures that each linear encoder can pass the calibration of the laser intrferometer smoothly.

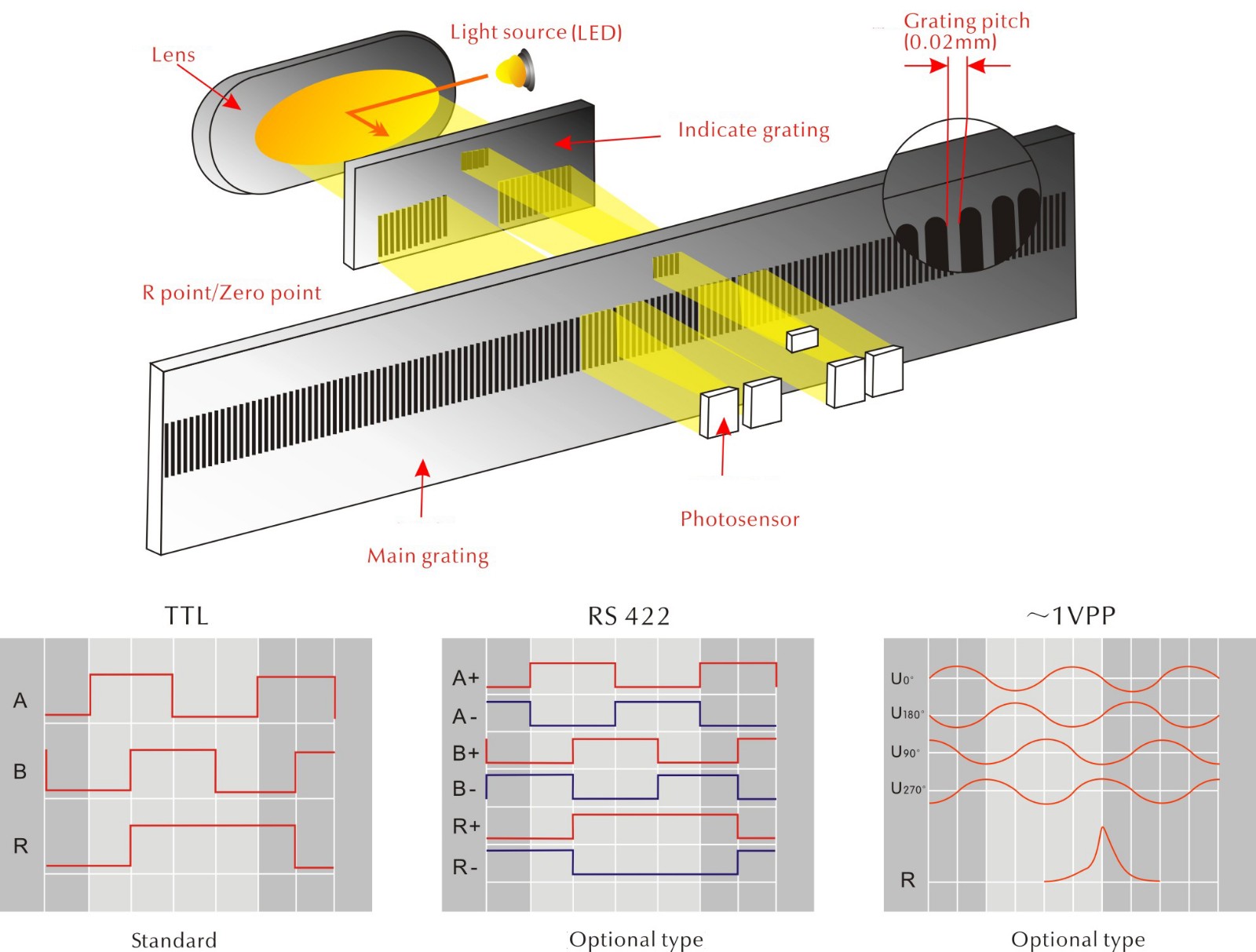

3.Output Signal Schematic Diagram3

| Product Name | Linear Scale SG Series | ||

| Model | SG1 | SG0.5 | SG0.1 |

| Resolution | 1μm | 0.5μm | 0.1μm |

| Max. Working Speed | 60m/min | 60m/min | 10m/min |

| Grating Pitch | 20μm | 20μm | 10μm |

| Output Signal | TTL,RS422 | TTL,RS422 | TTL,RS422 |

| Grating Measuring System | Transmission infrared optical measurement system, infrared wavelength:880(um) | ||

| Measuring Length | 25~600mm | ||

| Scan Unit Rolling System | 90° five ball bearing rolling system | ||

| Working Voltage | 5V±5%DC | ||

| Working Enviroment | Temperature : -10~45°C; Humidity:≤90% | ||

| Accuracy | 50≤ML≤500mm : Accuacy: ±3μm | ||

| 510≤ML≤600mm: Accuracy: ±5μm | |||

Sinowon Precision Linear scales of Optical Measuring Machines | |||||||||

Working Length (mm) | 50 | 100 | 150 | 200 | 250 | 300 | 400 | 500 | 600 |

Resolution 1um | SG1-050 | SG1-100 | SG1-150 | SG1-200 | SG1-250 | SG1-300 | SG1-400 | SG1-500 | SG1-600 |

Resolution 0.5um | SG0.5-050 | SG0.5-100 | SG0.5-150 | SG0.5-200 | SG0.5-250 | SG0.5-300 | SG0.5-400 | SG0.5-500 | SG0.5-600 |

Resolution 0.1um | SG0.1-050 | SG0.1-100 | SG0.1-150 | SG0.1-200 | SG0.1-250 | SG0.1-300 | SG0.1-400 | SG0.1-500 | SG0.1-600 |

Remark: The standard signal is single TTL, the optional signal is double TTL. 6.Scales Connector pin functions:

| Pin No. | Signal | Signal Wire Color | Type | Current Spec |

| 1 | +5V | Red | Imput | 35mA |

| 2 | 0V | Orange | Imput | 35mA |

| 3 | A | Yellow | Output | 4mA |

| 4 | B | Green | Output | 4mA |

| 5 | R | Brown | Output | 4mA |

| 6 | — | — | — | — |

| 7 | — | — | — | — |

| 8 | — | — | — | — |

| 9 | FG | Silver | — | — |

Copyright © 2018 Sinowon Innovation Metrology Manufacture Limited. | All Rights Reserved 粤ICP备16062806号

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.