Brief Induction:

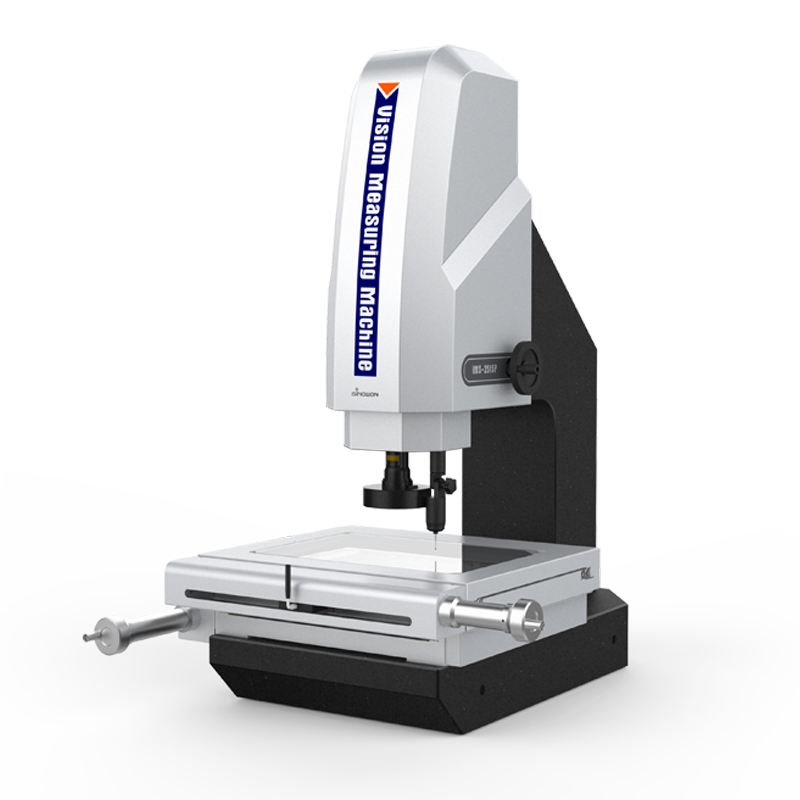

iTouch is the high accuracy geometric vision measuring machines that integrate the optical detent zoom lens and 3D touch trigger probe system, it is widely applied at the industry of 3C, semiconductor, PCB, automobile parts, medical parts, precise molds, aviation and aerospace, etc.

Product Characteristic:

l High precision marble base and pillar ensures the high stability of vision measuring system;

l High precision toothless rod and fast moving locking device ensures repeatability error is less than 2um;

l High precise working stage with 0.5um optical linear scales ensures the accuracy is less than 2.5+L/200um;

l High definitive detent zoom lens and high resolution digital camera ensures clear image without distortion;

l With programmable surface 4-ring 8-division LED Cold Illumination and contour LED telecentric illumination and built-in intelligent light adjustment, it can automatic control the brightness in the 4-ring 8-division;

l Britain touch trigger probe and powerful function iMeasuring3.1 3D Measuring Software, highly enhance the quality control.

Technical Specification:

Mode | iMS-2010P | iMS-2515P | iMS-3020P | iMS-4030P | iMS-5040P |

Code# | 521-140P | 521-150P | 521-160P | 521-170P | 521-180P |

Working Table | 270x350mm | 408x308mm | 458x358mm | 608x470mm | 650x580mm |

Material | Marble Table | Metal Table | Metal Table | Metal Table | Marble Table |

Glass Table | 142x242mm | 306x198mm | 356x248mm | 456x348mm | 541x441mm |

X/Y-axis Travel | 200x100mm | 250x150mm | 300x200mm | 400x300mm | 500x400mm |

Z-axis Travel | High-precision linear guide , working travel 200mm | ||||

X/Y/Z-axis Travel | 0.0005mm | ||||

X/Y-axis Accuracy | ≤2.5+L/200(um) | ||||

Hysterisis Error | 2um | ||||

Base and Pillar | High Accuracy Jinan Qing Marble | ||||

Illumination System(Software Adjustment) | Surface: Adjustable 0~255 grade 4-ring 8-division LED Cold Illumination, every division can be adjust independently | ||||

Contour: LED Parallel Illumination | |||||

LED Laser Navigation Lights | |||||

CCD Camera | High Resolution Digital Camera | ||||

Zoom lens | 6.5X High Resolution Detented Zoom Lens | ||||

Magnification:0.7X~4.5X;Video Magnification:26X~172X | |||||

Working Environment | Temperature:20℃±2℃, change range < 2℃/hr | ||||

Humidity:30% ~80%RH | |||||

Vibration<0.002g,<15Hz | |||||

Measuring Software | IMeasuring3.1 | ||||

Operation System | Support XP,WIN7,WIN8.1,WIN 10,32/64 operating system | ||||

Language | English, Simplified Chinese, Traditional Chinese, other language versions can be added | ||||

Dimension(W*D*H) | 677x552x998mm | 790x617x1000mm | 838x667x1000mm | 1002x817x1043mm | 1104x852x1085mm |

Net Weight | 150Kg | 175Kg | 185Kg | 350Kg | 380Kg |

Copyright © 2018 Sinowon Innovation Metrology Manufacture Limited. | All Rights Reserved 粤ICP备16062806号

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.