efficient metallographic polishing design for aerospace

1. Sinowon metallurgical polisher is precision-designed with the of our professionals with sharp observation.

2. The product is free of burrs on its surface. The adopted mold structure is reasonable to refuse any burrs during production.

3. The product is corrosion resistant. The metal materials used are able to withstand damage caused by oxidization or other chemical reactions.

4. This product meets the general needs of customers in the industry.

The CMP-250S is a castable vacuum chamber for cold mounting. It can significantly improve penetration of voids and provide better edge retention. This machine is designed for impregnation of porous materials, such as specimens for failure analysis with cracks, porous casts, electronic components, rocks minerals, ceramics, etc. Its large vacuum chamber allows for 11 1.5inch molds to be processed simultaneously. Coloured HMI touch screen and built-in vacuum pump allows the users to set pressure and time easily.

Product Feature

◆ 4 inch coloured touch screen, easy to use;

◆ Built-in vacuum pump and pressure sensor keeps user setting vacuum in the chamber;

◆ The vacuum pump stops automatically when time is over;

◆ Large vacuum chamber;

◆ Transparent cover, easy to observe samples;

◆ Retractable arm, easy to use;

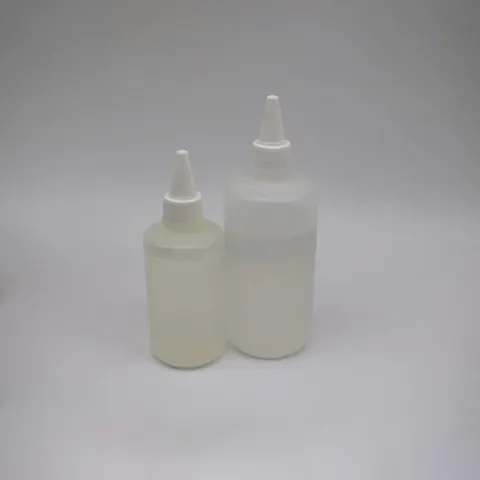

◆ Applications: epoxies resins, acrylic resins, Polyester resin, etc.

Specification

Description | CMP-250S |

Ultimate Vacuum | 80Pa |

Mold size | ● 30mm ○ 1,1.25,1.5, 2.0inch○Rectangular |

Power | 110-220V,50/60Hz, Single Phase |

Chamber (WxDxH) | 300*300*300 |

Pump(WxDxH) | 180*150*110 |

Weight | 4Kg |

Epoxies resins | ● 1sets |

Mould Release | ○ 250ml |

●Standard○Option

Insert hard mould silicone soft film

Epoxy Set

Acrylic Suit

Company Features

1. Sinowon Innovation Metrology Manufacture Limited. is a time-proven manufacturer of metallurgical polisher from China. We have been engaging the design and manufacture.

2. Sinowon Innovation Metrology Manufacture Limited. is technologically leading in metallographic polishing field.

3. During the course of development, we have aware of the importance of sustainability issues. We have established clear goals and plans to set our actions to gear to achieve sustainable development. We are fully aware of our responsibility to be the steward of the green environment. We are proud to be able to develop environmental awareness and sustainability programs across the company. We are always looking for ways to reduce energy, protect natural resources, recycle or eliminate waste. Check it! We implement the Sustainability Policy. In addition to complying with existing environmental laws and regulations, we practice a forward-looking environmental policy that encourages responsible and prudent use of all resources throughout the manufacture. Check it!

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.