elegant metallographic polishing design for aerospace

1. Sinowon Innovation Metrology Manufacture Limited. is more technically advanced in manufacturing metallographic polishing .

2. This product is crease resistant. It is made with wrinkle-resistant fabric, thus it won't have any creases when it is compressed or folded.

3. This product promotes a clear distribution of responsibilities. Operators with specific roles are able to complete their assigned tasks more efficiently.

The AC-250 series are tabletop/floor standing automatic cutters with high performance. This is a versatile cutting machine designed for sectioning an extremely wide range of materials, such as metals, fasteners, rocks and ceramics, polymers, composites, electronics, semiconductors, biomaterials, etc. The machine integrates the optimized precision cutting technology with advanced control system to provide excellent cut quality and high throughput.

Product Feature

◆ Powerful motor to reduce cutting time and provide high productivity

◆ Smart feed. The machine can adjust the feed speed in real time with the load changes

◆ Cutting modes: Y-continuous, Y-pulse, Z-continuous, Z-pulse, slicing (different model, different cutting mode)

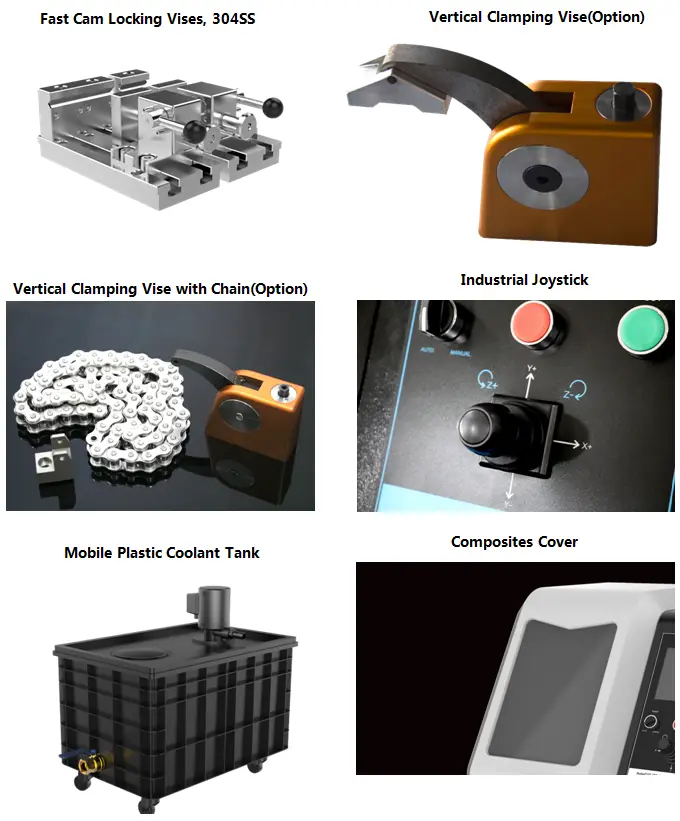

◆ Versatile industrial joystick with X, Y, Z axis. Easy to use

◆ 8 inch color touchscreen for simple operation and user friendliness

◆ Electrical brake for faster stopping of the blade

◆ Chamber illumination with LED

◆ Aluminum casting base, powder coated

◆ T-slot Table made of stainless and aluminum alloy

◆ Fast Cam Locking Vises, made of 304 stainless steel

◆ Left cover made of composites by integral molding

◆ Mobile plastic recirculation coolant tank

◆ Independent pump for cleaning the chamber

◆ Optional laser alignment aid

Specification

Description | AC-250XYZ | AC-250YZ | AC-250Z |

Y Feed | Automatic | ||

Z Feed | Automatic | Automatic | --- |

X Feed | Automatic | ○Manual | ○Automatic○Manual |

Cutting mode | Continuous, Pulse | Continuous, Pulse | Continuous, Pulse |

Blade(mm) | 250*32*1.5 | ||

Blade speed (rpm) | 500-3000 | ||

Table Dimensions (WxD,mm) | 279*260 | ||

X Travel | 60mm | ||

Cooling | Automatic/manual | ||

Main Motor | 2.2KW | ||

Power | 110/220V AC, 50-60Hz, 1 Phase | ||

Accessories | |||

Diamond Blade | ○ | ○ | ○ |

SiC blade | ○ | ○ | ○ |

Alumina Blade | ● | ● | ● |

Fast Cam Locking Vises | ● | ● | ● |

Vertical Clamping vise | ○ | ○ | ○ |

Laser alignment aid | ○ | ○ | ○ |

Plastic tank | ● | ● | ● |

Plastic tank with magnetic filter | ○ | ○ | ○ |

Cutting fluid | ○ | ○ | ○ |

Centrifugal separator | ○ | ○ | ○ |

Base Bench | ○ | ○ | ○ |

●standard○option

Details

Company Features

1. Sinowon Innovation Metrology Manufacture Limited. outshines other metallographic polishing manufacturers now for premium quality and affordable price.

2. Our employees are our most important asset. The dynamic team is distinguished by its agility, effective communication, and professionalism. All these have provided the company with a strong foundation to better serve clients.

3. Our company bears social responsibility. We take critical steps to develop sustainability in our operations with training and a material library. Our mission is to create value for the customer through trust, innovation, functionality, comprehensive designs, and technology-driven operations & manufacturing processes. Delivering high-quality products is critical to our purpose. Our focus on quality excellence includes continuously enhancing our standards, technology, and training for our people, as well as learning from our mistakes. We uphold business ethics. We will be a trustworthy partner by adhering to the values of honesty and protecting clients' privacy on product design.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.