elegant metallographic polishing design for electronic industry

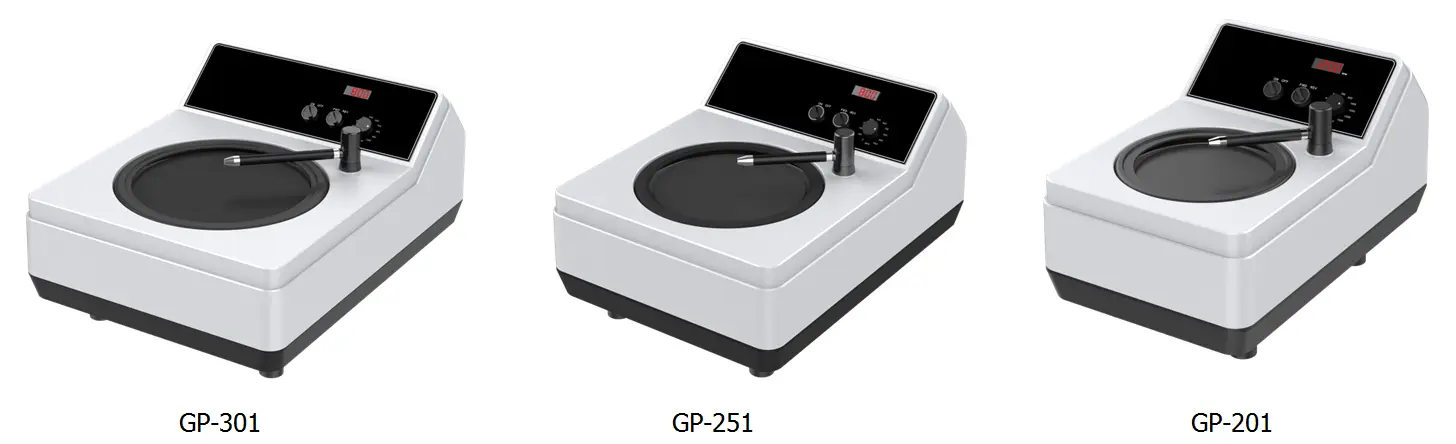

GP-201/251/301 are single wheel grinder and polisher for metallographic specimen preparation. The strong and variable speed drive allows application for all working steps.

Product Feature

◆ Simple operation for grinding and polishing;

◆ Variable speed. It is determinable through a rotating switch and shown digitally on the display;

◆ CCW and CW direction control;

◆ The water hose with universal direction can be pulled out for cleaning the basin;

◆ Plastic disposable bowl liner for ease of cleaning;

◆ Hard anodized aluminum working wheel;

◆ Durable composite construction, antirust;

◆ Powder coated aluminum housing, durable and reliable.

Specification

Description | GP-201 | GP-251 | GP-301 |

Wheel (mm) | Ø203 | ○Ø203●Ø254 | ○Ø203 ○Ø254 ●Ø305 |

Speed(rpm) | 100-1000 | 100-1000 | 100-1000 |

Motor | 500W | 600W | 600W |

Power | 110/220V | ||

Paper Ring | ● | ● | ● |

Splash guard | ● | ● | ● |

Cover | ● | ● | ● |

Grinding paper | ● | ● | ● |

Polishing Cloth | ● | ● | ● |

Diamond Spray | ○ | ○ | ○ |

Diamond Slurry | ○ | ○ | ○ |

Alumina Powder | ○ | ○ | ○ |

Recirculating Tank | ○ | ○ | ○ |

●Standard○Option

Details

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.