excellent metallographic polishing inquire now for electronic industry

1. metallographic polishing is manufactured under the visionary guidance of experts in accordance with global market standards with the aid of pioneering techniques. It is well recognized by more than 5000 customers

2. The product is a necessary one in today's fast-paced and busy world. It will definitely help improve overall production efficiency. Its packing is made seriously to guarantee the safety during shipment

3. This product has the required strength. It can help prevent the packaged item from damage during storage and transportation. It is aimed at more than 60 countries and regions for exports

4. This product has clearly printed texts. It can display information about the item such as materials, operation instructions, etc. It has been marketed successfully for 12 years, thanks to the excellence in quality and technology

5. It is able to allow sweat to wick away instead of absorbing it, keeping the sleeper cooler and drier at night. The product is excellent in dust prevention

The AC-300 series are floor standing automatic cutters with high performance. This is a versatile cutting machine designed for sectioning an extremely wide range of materials, such as metals, fasteners, rocks and ceramics, polymers, composites, electronics, semiconductors, biomaterials, etc. The machine integrates the optimized precision cutting technology with advanced control system to provide excellent cut quality and high throughput.

Product Feature

◆ Powerful motor to reduce cutting time and provide high productivity

◆ Smart feed. The machine can adjust the feed speed in real time with the load changes

◆ Cutting modes: Y-continuous, Y-pulse, Z-continuous, Z-pulse, slicing (different model, different cutting mode)

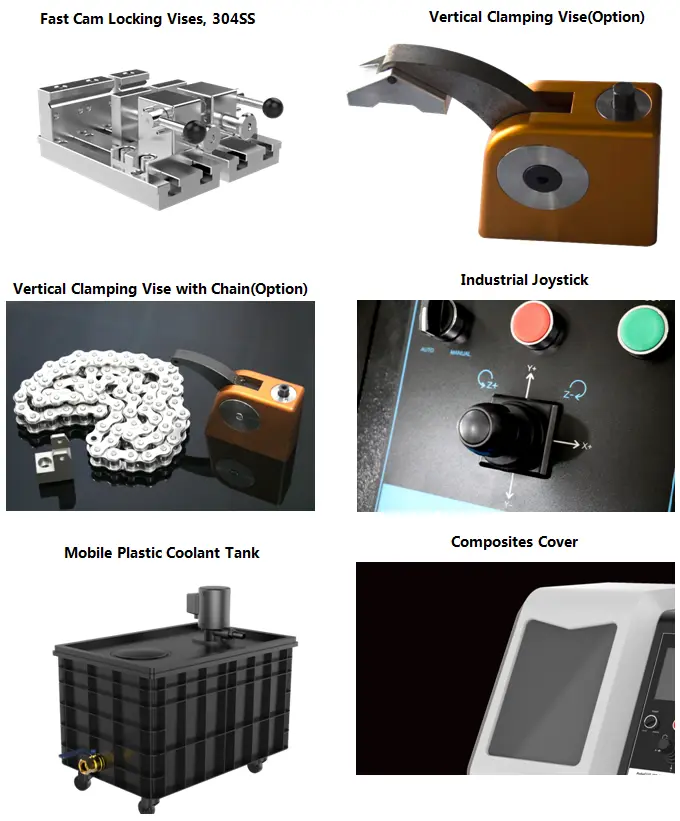

◆ Versatile industrial joystick with X, Y, Z axis. Easy to use

◆ 8 inch color touchscreen for simple operation and user friendliness

◆ Electrical brake for faster stopping of the blade

◆ Chamber illumination with LED

◆ Aluminum casting base, powder coated

◆ T-slot Table made of stainless and aluminum alloy

◆ Fast Cam Locking Vises, made of 304 stainless steel

◆ Left cover made of composites by integral molding

◆ Mobile plastic recirculation coolant tank

◆ Independent pump for cleaning the chamber

◆ Optional laser alignment aid

Specification

Description | AC-300XYZ | AC-300YZ | AC-300Z |

Y Feed | Automatic | ||

Z Feed | Automatic | Automatic | --- |

X Feed | Automatic | ○Manual | ○Automatic○Manual |

Cutting mode | Continuous, Pulse | Continuous, Pulse | Continuous, Pulse |

Blade(mm) | 300*32*1.8 | ||

Blade speed (rpm) | 500-3000 | ||

Table Dimensions (WxD,mm) | 350*260 | ||

X Travel | 80mm | ||

Cooling | Automatic/manual | ||

Main Motor | 3.0KW | ||

Power | 110/220V AC, 50-60Hz, 1 Phase/3 Phase | ||

Accessories | |||

Diamond Blade | ○ | ○ | ○ |

SiC blade | ○ | ○ | ○ |

Alumina Blade | ● | ● | ● |

Fast Cam Locking Vises | ● | ● | ● |

Vertical Clamping vise | ○ | ○ | ○ |

Laser alignment aid | ○ | ○ | ○ |

Plastic tank | ● | ● | ● |

Plastic tank with magnetic filter | ○ | ○ | ○ |

Cutting fluid | ○ | ○ | ○ |

Centrifugal separator | ○ | ○ | ○ |

●Standard○Option

Details

Company Features

1. Over the years, the gross sales volume of our company goes up. After devoting much effort in expanding markets, we have increased cooperations with customers around the world.

2. Sustainability is a core topic for us and determines our actions. We work profit-oriented with respect to our social and environmental responsibility.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.