approved metallurgical equipment inquire now for LCD

1. Once Sinowon metallurgical testing equipment is removed from the mold, it has to undergo further processing. It will be added to a variety of finishes and textures to add an aesthetic touch. A team of experienced talents is gathered to support the product sales

2. If you need high quality metallurgical equipment , it will be a wise choice to choose us. It is easy to operate, with fast speed

3. The product produced under the circumstances we set meets the strictest quality criteria. The product can be controlled in a motorized way, to eliminate errors caused by manual operation

The AC-250 series are tabletop/floor standing automatic cutters with high performance. This is a versatile cutting machine designed for sectioning an extremely wide range of materials, such as metals, fasteners, rocks and ceramics, polymers, composites, electronics, semiconductors, biomaterials, etc. The machine integrates the optimized precision cutting technology with advanced control system to provide excellent cut quality and high throughput.

Product Feature

◆ Powerful motor to reduce cutting time and provide high productivity

◆ Smart feed. The machine can adjust the feed speed in real time with the load changes

◆ Cutting modes: Y-continuous, Y-pulse, Z-continuous, Z-pulse, slicing (different model, different cutting mode)

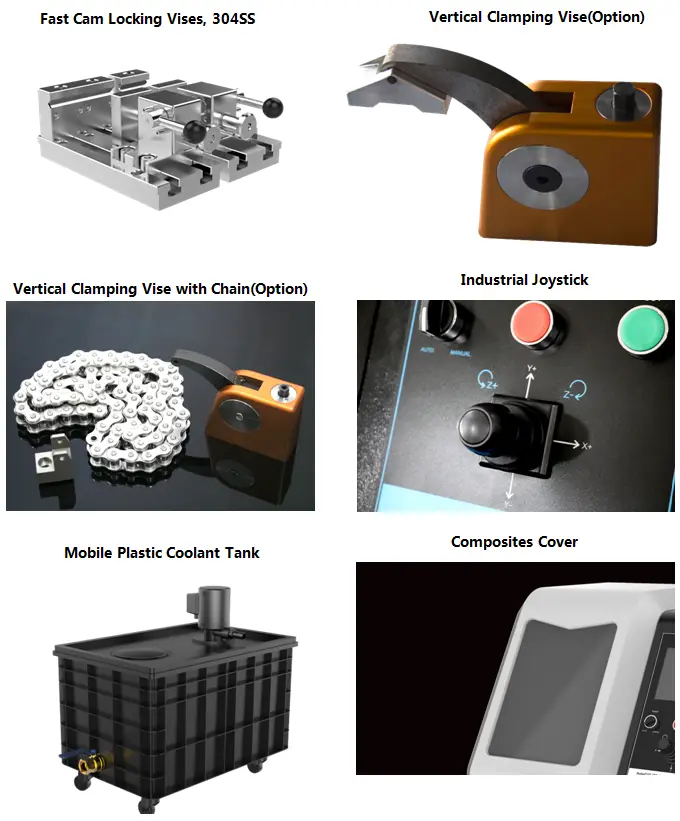

◆ Versatile industrial joystick with X, Y, Z axis. Easy to use

◆ 8 inch color touchscreen for simple operation and user friendliness

◆ Electrical brake for faster stopping of the blade

◆ Chamber illumination with LED

◆ Aluminum casting base, powder coated

◆ T-slot Table made of stainless and aluminum alloy

◆ Fast Cam Locking Vises, made of 304 stainless steel

◆ Left cover made of composites by integral molding

◆ Mobile plastic recirculation coolant tank

◆ Independent pump for cleaning the chamber

◆ Optional laser alignment aid

Specification

Description | AC-250XYZ | AC-250YZ | AC-250Z |

Y Feed | Automatic | ||

Z Feed | Automatic | Automatic | --- |

X Feed | Automatic | ○Manual | ○Automatic○Manual |

Cutting mode | Continuous, Pulse | Continuous, Pulse | Continuous, Pulse |

Blade(mm) | 250*32*1.5 | ||

Blade speed (rpm) | 500-3000 | ||

Table Dimensions (WxD,mm) | 279*260 | ||

X Travel | 60mm | ||

Cooling | Automatic/manual | ||

Main Motor | 2.2KW | ||

Power | 110/220V AC, 50-60Hz, 1 Phase | ||

Accessories | |||

Diamond Blade | ○ | ○ | ○ |

SiC blade | ○ | ○ | ○ |

Alumina Blade | ● | ● | ● |

Fast Cam Locking Vises | ● | ● | ● |

Vertical Clamping vise | ○ | ○ | ○ |

Laser alignment aid | ○ | ○ | ○ |

Plastic tank | ● | ● | ● |

Plastic tank with magnetic filter | ○ | ○ | ○ |

Cutting fluid | ○ | ○ | ○ |

Centrifugal separator | ○ | ○ | ○ |

Base Bench | ○ | ○ | ○ |

●standard○option

Details

Company Features

1. Sinowon Innovation Metrology Manufacture Limited. is an important national metallurgical equipment backbone enterprise with many years of operating history. Sinowon has been also specialized in researching and developing metallographic equipment with exquisite quality.

2. Was it not for our advanced technology, Sinowon Innovation Metrology Manufacture Limited. may not produce such high quality metallographic polishing .

3. One of the most important advantages lies in our high quality for polishing equipment. We have defined our business philosophy - We aim to provide the best outcome for our customers, in terms of products and services.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.