precise polishing equipment design for electronic industry

1. The production of Sinowon metallurgical instruments covers a wide range of stages. They include the procurement of raw materials, parts processing, secondary processes such as plating and anodizing, complete mechanical assembly, and testing. It is well recognized by more than 5000 customers

2. The product will finally contribute to improving people's working efficiency. Its intelligence makes many tasks be completed easier and faster. The product performs well in program control and material use reduction

3. In order to ensure the quality of the product, our expert team will careful and strictly check the quality in every stage of production. Imported materials and accessories are used in product manufacturing

The CMP-250S is a castable vacuum chamber for cold mounting. It can significantly improve penetration of voids and provide better edge retention. This machine is designed for impregnation of porous materials, such as specimens for failure analysis with cracks, porous casts, electronic components, rocks minerals, ceramics, etc. Its large vacuum chamber allows for 11 1.5inch molds to be processed simultaneously. Coloured HMI touch screen and built-in vacuum pump allows the users to set pressure and time easily.

Product Feature

◆ 4 inch coloured touch screen, easy to use;

◆ Built-in vacuum pump and pressure sensor keeps user setting vacuum in the chamber;

◆ The vacuum pump stops automatically when time is over;

◆ Large vacuum chamber;

◆ Transparent cover, easy to observe samples;

◆ Retractable arm, easy to use;

◆ Applications: epoxies resins, acrylic resins, Polyester resin, etc.

Specification

Description | CMP-250S |

Ultimate Vacuum | 80Pa |

Mold size | ● 30mm ○ 1,1.25,1.5, 2.0inch○Rectangular |

Power | 110-220V,50/60Hz, Single Phase |

Chamber (WxDxH) | 300*300*300 |

Pump(WxDxH) | 180*150*110 |

Weight | 4Kg |

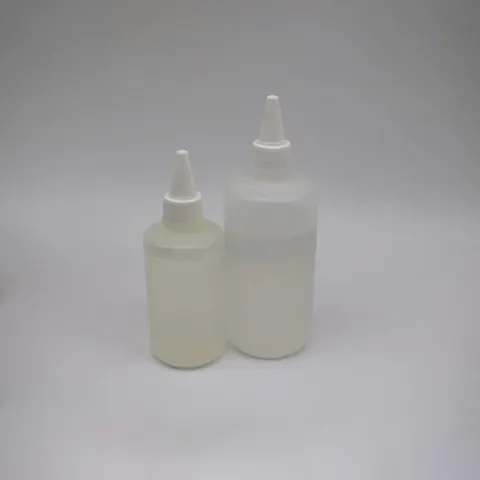

Epoxies resins | ● 1sets |

Mould Release | ○ 250ml |

●Standard○Option

Insert hard mould silicone soft film

Epoxy Set

Acrylic Suit

Company Features

1. With core technology, Sinowon has succeeded in taking this chance of developing polishing equipment which is of high performance in metallurgical instruments .

2. We are working hard to create leadership for environmental sustainability. We believe that our company in combination with a well-integrated corporate sustainability strategy can help tackle a range of global challenges. This is how we work with technological advancement to continue to be a responsible and relevant driver of positive change in society. Inquire online!

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.