Sinowon brinell hardness to rockwell manufacturer for soft alloys

1. The quality process of Sinowon brinell hardness to rockwell begins with a full contract review of each order. Each component is reviewed for mechanical performance prior to production. The production is supported by professional engineers

2. Sinowon Innovation Metrology Manufacture Limited. has strong growth, upgrade and optimization capabilities. The product is well known for high accuracy and great stability

3. The quality of this product is more assured by stressing the value of quality management. It is aimed at more than 60 countries and regions for exports

4. The product is durable and has a good performance, which has been approved by the international quality certificates. The quality is reliable and the service life is long

Product Feature

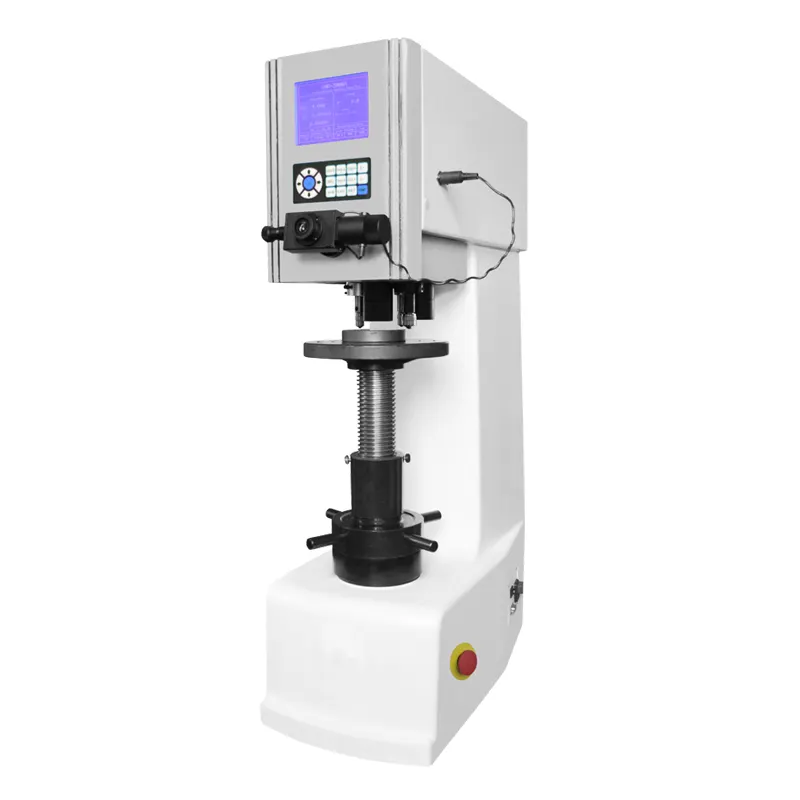

◆ AutoBrin-3000A is the latest generation digital Brinell hardness tester, it equips with motorized turret to install 10mm, 5mm, 2.5mm tungsten carbide ball indenter, 1x and 2x objectives simultaneously, avoid operation error during switch indenter and objectives.

◆ Apply large LCD to display testing parameters and results, indentation can be measured by 10x digital eyepiece, also available to realize hardness conversion among 17 hardness scales.

◆ Loading control by load cell with accuracy at 0.5‰, microchip can make force compensation automatically lost during loading.

◆ Indentation measurement system integrated by 10x digital eyepiece, 1x and 2x objectives, eliminates manually brinell table checking, to realize directly indentation measurement and display hardness result on LCD.

◆ AutoBrin-3000A equips with built-in mini printer, and can transfer data to computer by RS232, to do further analysis by PC software.

◆ Optional accessory for AutoBrin-3000A has Brinell Optical Measuring System BrinScan.

Application

Because of brinell method apply big loading force and generate big indentation, it is suitable to test hardness of coarse-grained metals, like cast iron, non ferrous metal and their alloy, sale of steels, etc.

Soft metals are also available to test, like Aluminium, copper, plumbum, tin, zinc and their alloy, etc.

Specification

| Name | Auto Turret Digital Brinell Hardness Tester | |

| Model | AutoBrin-3000A | |

| Code# | 831-151 | |

| Loading Force | Kgf | 62.5Kgf, 100Kgf, 125Kgf, 187.5Kgf, 250Kgf, 500Kgf, 750Kgf, 1000Kgf, 1500Kgf, 3000Kgf |

| N | 612.9N, 980N, 1226N, 1839N, 2452N, 4900N, 7355N, 9800N, 14700N, 29400N | |

| Hardness Resolution | 0.1HBW | |

| Brinell Range | (8-650) HBW | |

| Hardness Reading | Display on LCD | |

| Indentation Measurement | Magnification 10x/20x, eyepiece 10x and objective 1x, 2x | |

| Data Output | Mini printer/RS232 | |

| Vertical Space | 260mm | |

| Horizontal Space | 150mm | |

| Dimension | 890×535×260mm | |

| Gross/Net Weight | 180Kg/150Kg | |

| Power Supply | AC 220V/110V±5%,50~60 Hz | |

| Conform Standard | GB/T231.2, JJG150, EN-ISO 6506; ASTM E10-12; JIS Z2243 | |

Accuracy | ||

| Hardness Range | Permitted Error | Repeatability |

| HBW≤ 125 | ≤± 3.5% | ≤ 3.5% |

| 125<HBW≤225 | ≤± 2.5% | ≤ 3.0% |

| HBW> 225 | ≤± 2.0% | ≤ 2.5% |

Company Features

1. Excellent in supplying brinell hardness to rockwell of top quality, Sinowon is famous for the considerate service also.

2. Our quality is our company name card in brinell hardness testing machine industry, so we will do it best.

3. We stick to integrity. We ensure our principles of integrity, honesty, quality, and fairness are incorporated into our business practices on a global scale.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.