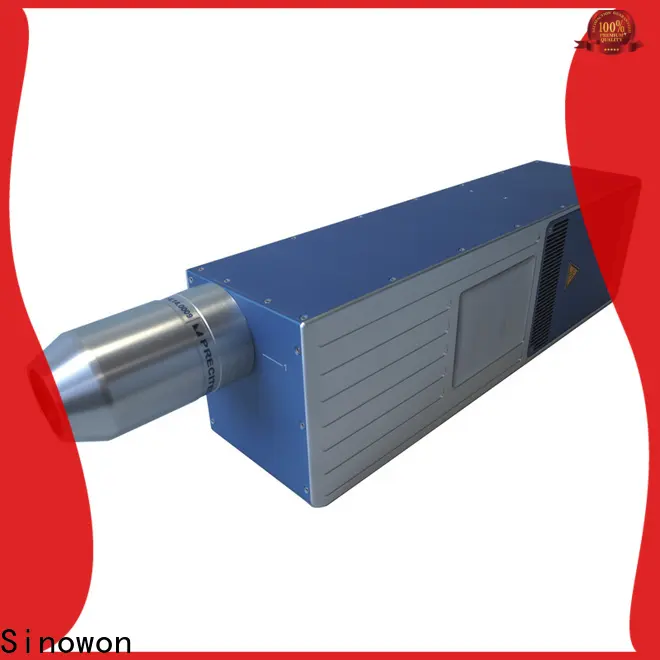

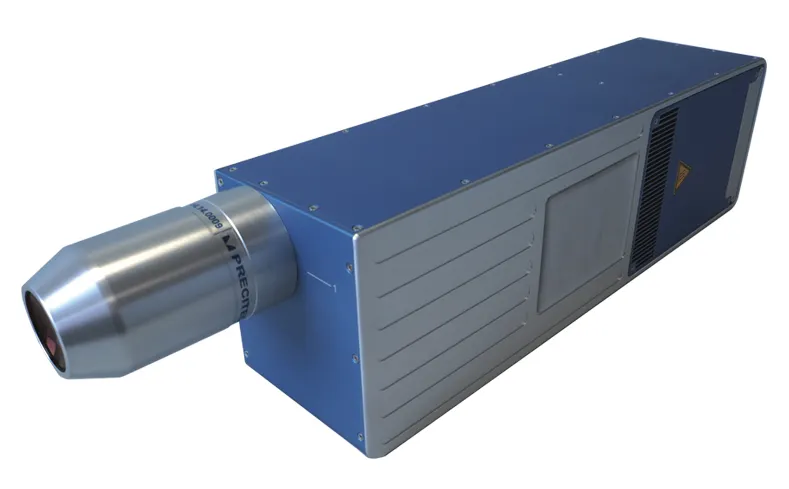

CHRocodile CLS, the PRECITEC chromatic confocal line sensor offers an incredibly fast 3D measurement of 384,000 points persecond with nanometric scale resolution. Thanks to its robust and highly integrated design, CHRocodile CLS is perfectly suited for easy integration into inspection machines in the production line, including harsh industrial environments. An outstanding dynamic range and an excellent signal to noise ratio make the CHRocodile CLS the best measuring tool for all materials – including polished and highly tilted surfaces. With its unrivaled performance/price ratio, CHRocodile CLS is the best choice for ultrafast 3D inspection.

Characteristics

EFFICIENT

◆High-speed

◆Non-contact

◆Precise

VERSATILE

◆Instantaneous profile measurement

◆Inline inspection

◆Interchangeable optical probes

◆Distance and Thickness

User Friendly

◆Maintainance-free

◆Easy to integrate

◆Robust

Technical Specifications Chrocodile CLS Series

Application | Distance, thickness |

Lines /second | 100 - 2000, optionally 6000 Hz1) |

Number of points / line | 192 |

Measuring Range | Depends on optical probe |

Synchronization with external devices | Trigger input, synchronizing output, 5 encoder inputs |

Interface | Ethernet, service ports: RS-422, USB |

Transfer Rate | 100 Mbit (Ethernet), 9600 - 921600 Baud (RS-422), 921600 Baud (USB: virtual comport) |

Light Source | LED |

Operating Temperature | +5°C up to +50°C |

Storage Temperature | -20°C up to +70°C |

Dimension without probe (w x h x d) | 391 mm x 100 mm x 114 mm |

Weight | 4 kg |

Protection Class | IP 50 (DIN 40050/ IEC 144) |

Supply Voltage | 24 +/- 10% V DC (with separate power supply 100 - 240 V AC / 50 Hz - 60 Hz) |

Rated Power | 40 W |

Note | SDK available. NET Framework 4 and higher compatible |

Order Number | 5007994 (straight); 5007995 (90° angled); 5008859 (frequency upgrade up to 6000 Hz) |

1) With reduction of measuring range

Technical Specifications of Optical Probes

Model | CLS 0.2 | CLS 0.5 | CLS 1 | CLS 2 | CLS 2.3 | CLS 4 |

Measuring Range | 200 μm | 500 μm | 950 μm | 2000 μm | 2300 μm | 3900 μm |

Line length | 0.96 mm ± 0.01 mm | 1.43 mm ± 0,02 mm | 1.91 mm ± 0.02 mm | 8.3 mm ± 0.1 mm | 1.53 mm ± 0.02 mm | 4.78 mm ± 0.04 mm |

Pitch | 5 μm ± 0.05 μm | 7.5 μm ± 0.08 μm | 10 μm ± 0.1 μm | 43.5 μm ± 0.5 μm | 8 μm ± 0.08 μm | 25 μm ± 0.25 μm |

Working distance1) | 5.3 mm ± 0.4 mm | 12 mm ± 0.4 mm | 18.5 mm ± 0.5 mm | 27.5 mm ± 0.5 mm | 15.6 mm ± 0.5 mm | 36.4 mm ± 0.6 mm |

Spot diameter | 2 μm | 3 μm | 4 μm | 17 μm | 3.2 μm | 10 μm |

Lateral resolution | 1 μm | 1.5 μm | 2 μm | 8.5 μm | 1.6 μm | 5 μm |

Axial resolution | 20 nm | 50 nm | 80 nm | 250 nm | 200 nm | 320 nm |

Linearity 2) | ± 80 nm | ± 200 nm | ± 300 nm | ± 1 μm | ± 780 nm | ± 1.2 μm |

Numerical aperture | 0.7 | 0.61 | 0.55 | 0.2 | 0.55 | 0.33 |

Measurement angle to surface3) | 90°+/-44° | 90°+/- 38° | 90°+/-33° | 90°+/-11° | 90°+/-33° | 90°+/-20° |

Thickness measuring range4) | 20 μm - 280 μm | 40 μm - 700 μm | 75 μm - 1.35 mm | 280 μm - 2800 μm | 200 μm - 3.1 mm | 300 μm - 5.5 mm |

Photometric efficiency5) | 7 | 10 | 14 | 50 | 2 | 22 |

Length | 70.4 mm | 75 mm | 93.3 mm | 84 mm | 99 mm | 120 mm |

Diameter | 37 mm | 52 mm | 54 mm | 55 mm | 54 mm | 58 mm |

Weight | 190 g | 240 g | 430 g | 200 g | 390 g | 510 g |

Order number | 5007993 | 5009885 | 5007895 | 5009888 | 5009128 | 5007896 |

1) Bottom of optical probe to middle of measuring range

2) Perpendicular measurement on mirror at 20° C

3) Decreasing accuracy on the limits

4) Refractive index n = 1.5

5) Estimated average signal intensity in % obtained on uncoated glass at 2 kHz, LED 100 %, in the center of the measuring range.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2026 Sinowon | All Rights Reserved.