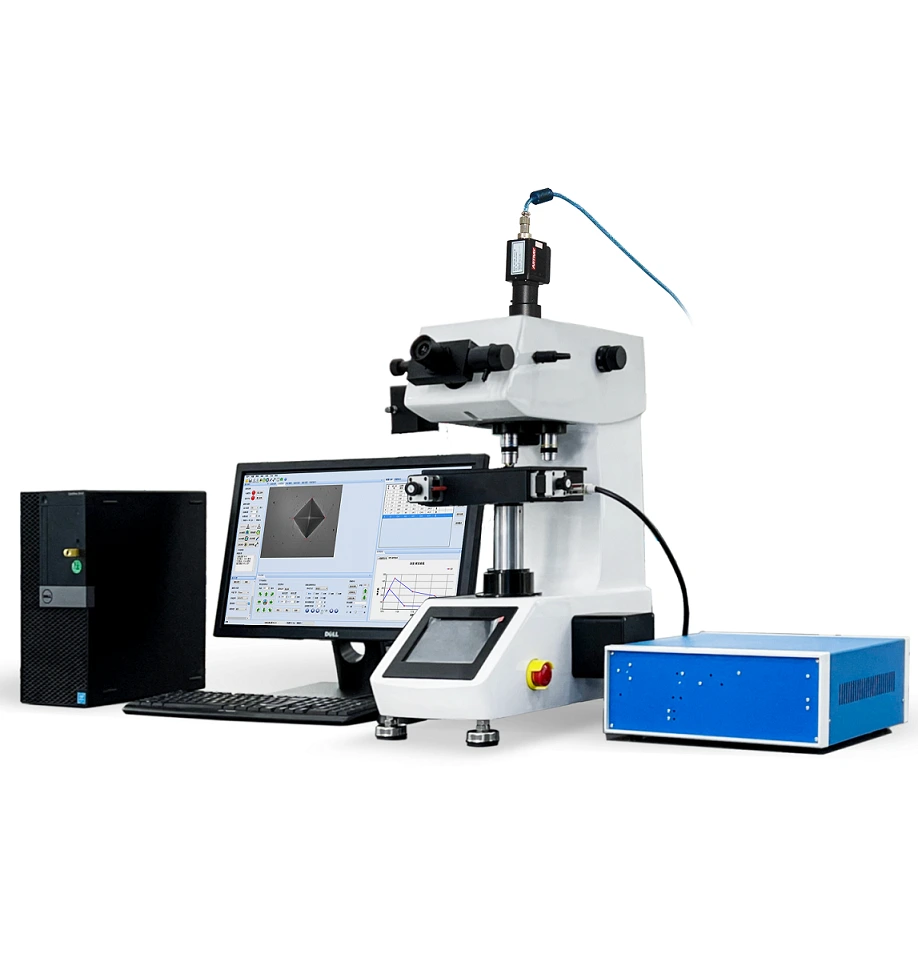

AutoVicky ZHV-VH1010 Automatic MicroVickers Hardness Tester

Vickers method is based on an optical measurement system, it specifies a range of light loads using a diamond indenter to make an indentation which is measured and converted to a hardness value. It is very useful for testing on a wide type of materials, but test samples must be polished to enable measuring the size of the impressions. A square base pyramid shaped diamond is used for testing in the Vickers scale. Typically loads are very light, ranging from 10gm to 1Kgf, although "Macro" Vickers loads can range up to 50 Kg or more.

Application

AutoVicky ZHV-VH1010 is an automatic micro-Vickers hardness testing system with machine vision, motorized X-Y platform and computer software system, it is applied to test Vickers hardness scales of metals, ceramics, and composites. Since the test indentation is very small in a Vickers test, it is useful for a variety of applications: testing very thin materials like foils or measuring the surface of a part, small parts or small areas, measuring individual microstructures, or measuring the depth of case hardening by sectioning a part and making a series of indentations to describe a profile of the change in hardness.

Product Feature

◆ Excellent Boldy of VH1010 Micro Vickers Hardness Testers with linear displacement lifting structure for the weight loading system.

◆ Precise Eight-Class dead weight system from 10gf to 1000gf, and Automatic loading, dwelling, and unloading during the testing process.

◆ Stable automatic turret with 3-working-position, MicroVickers diamond indenter, 10x and 40x objective are installing on one focal plane.

◆ High-definition optical path with 5MPixel Camera makes the hardness indention sharply, the video magnification is over than 2000x, it makes the measurement of small indention easily.

◆ Motorized X-Y platform with metal size 110x100mm and measuring stoke is 50x50mm, it can be programmed to test the Vickers hardness of specimen automatically.

◆ Z-axis Manual Focus System as standard delivery, it is optional about the Z-axis automatic focusing system.

◆ Powerful automatic Vickers testing software ATS-100 with smart testing functions

◆ Windows operating system, Word, Excel, PDF and other Customized output reports are available.

Specification

Commodity | Automatic MicroVickers Hardness Tester | |

Model | AutoVicky ZHV-VH1010 | |

Code# | 823-170-1010 | |

Loading Force | N | 0.098, 0.246, 0.49, 0.98, 1.96, 2.94, 4.90, 9.80 |

gf | 10, 25, 50, 100, 200, 300, 500, 1000 | |

Loading System | Automatic | |

Motorized X-Y Stage | Mini-Step-Motor with Size L:255*W:205mm | |

X-Y Stage Stroke | 50x50mm | |

Minimum step: | 0.625um | |

Language | English | |

Loading Time | 1~60s adjustable | |

Turret | Automatic-turret | |

Objective | 10×, 40× | |

Z-axis Focusing System | Manual-Focus by Worm Gear System | |

Minimum Measurement Unit | 0.025 μm | |

Max. Height of Specimen | 90mm | |

Instrument Throat | 120mm | |

Executive Standard | GB/T 4340.2; ISO 6507; ASTM E92; JIS Z2244 | |

Power Supply | 220 VAC, 50/60 Hz | |

Dimension (L×W×H) | 425×245×530mm | |

Automatic Testing Software | ATS-100 Image Analysis and Measurement Software (Dongle and CD) | |

Camer Type | 5 Megapixel HD Camera | |

Camera Adapter Tube | ZHV-VH1010-1X | |

Motion Controller | X-Y Automatic Platform Control System | |

Computer System | Dell 3090MT | |

Monitor | 21.5” HDMI Monitor | |

Net Weight | 55kg | |

Gross Weight | 70kg | |

Software Advantages

◆ It can scan the whole picture, scan the whole picture of the product to the computer, select any position, and the product will automatically move to the required position.

◆ It can support 17 Ways of path planning, set any number, such as 30-point coordinates, click start, and the machine will automatically complete 30-point measurement without manual operation, automatic loading, automatic focusing and automatic measurement.

Basic Function

◆ The automatic recognition ability of indentation image is leading, and the detection efficiency, stability and accuracy of detection results are high.

◆ Two kinds of calibration: optical calibration, (manual / automatic) hardness block calibration. The hardness block supports multiple averaging, arbitrary multiple standard blocks and segmented calibration and preferred measurement.

◆ In addition to automatic measurement, there are three manual measurement options: four side measurement, diagonal measurement and four-point measurement (the order of four vertex selection can be arbitrary).

◆ Three types of indentation marks are supported: "Rectangle", "Red Cross" and "Circular".

◆ During manual measurement, it has the function of magnifying glass, which is convenient to find the indentation vertex position;

◆ The unique keyboard shortcut function can quickly move the selected vertex to make the measurement operation more efficient.

◆ Provide pixel distance and physical distance of indentation diagonal, and calculate HV / HK value under current load in real time.

◆ Automatic switching of turret (switching of objective lens and indenter).

◆ 5 million digital cameras to display indentation video on the computer. It can capture and store images.

◆ Real time display and update the status of current hardness tester: current indenter / objective lens, load holding time, loading force, etc.

◆ The distance between two points can be measured manually; Multiple groups of distances can also be displayed on the video or image at the same time.

◆ In case of different resolutions, different objective lenses and different loads, the software will automatically select the best calibration coefficient.

◆ All test point information can be identified and marked separately or according to customer requirements. The test point identification information will be displayed in the test value sequence table and indentation diagram for easy query. This function is very important for subsequent analysis and processing.

◆ Refer to GB, DIN, ISO, ASTM and other Hardness Conversion standards to realize: Vickers HV, Knoop HK; Rockwell: HRC, HRA, HRB, HRD, HRE, HRF, HRG, HRK; Surface Rockwell: HR15N, HR30N, HR45N, HR15T, HR30T, HR45T; realize mutual conversion between hardness values such as Brinell HBS and Brinell HBW.

◆ When measuring the hardened layer path sequence, there are multiple flexible initializations setting modes, which automatically save and import the previous path sequence; The measurement path can also be saved as desired for reloading.

◆ The path sequence measurement results automatically generate the corresponding hardened layer depth value and hardness change curve.

◆ Multiple analysis modes can be selected for measurement data; All results can be set into graphic report.

◆ Report content and format can be flexibly set, and WORD and EXCEL documents can be automatically generated.

◆ Password and management authority can be set: ordinary operators can only measure hardness according to the set settings.

◆ The built-in standard hardness value conversion tool can automatically convert the measured hardness value according to the table and list it in the result table.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Copyright © 2025 Sinowon | All Rights Reserved.