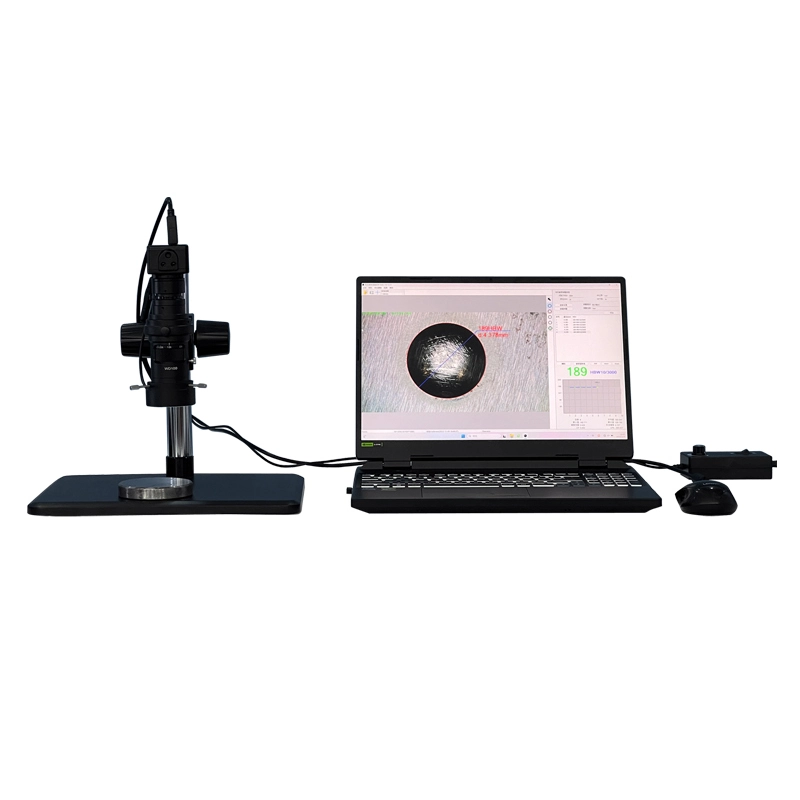

Brinell-Indention Optical Measurement System QB-310

Introduction:

lThe benchtop Brinell hardness indentation measurement microscope is an automated Brinell hardness indentation Optical measurement system developed for Windows based operating systems that can be used with any commercially available Brinell hardness tester to replace the traditional mechanical reading microscope and automatically measure the Brinell hardness value of a specimen.

lBrinell indentation Optical measuring system adopts advanced machine vision technology, through the digital microscope to photograph the indentation left by the specimen after the test force is loaded by the Brinell hardness tester, which can measure the Brinell hardness value of the specimen tested by different indenters of 10mm, 5mm, 2.5mm, 1mm.

lDuring the measurement process, there is no need for human to determine the indentation edge, no need for human to record the indentation length data, no need for human to find the hardness comparison table, automatic measurement, automatic recording, automatic saving, automatic generation of hardness test chart, and can set the upper and lower limits, automatic Ng and Pass determination.

lProfessional testers use mechanical reading microscope to measure hardness manually in about 2 minutes each time, the measurement process will produce multiple transmission errors, the measurement efficiency is very low, while the use of Brinell indentation Optical measurement system, without any professional and technical personnel, from the president of the company, down to the freshman general workers, can easily in less than 1 second to the indentation of accurate measurement.

lContinuous zoom lens is used to make the magnification switching more effortless and faster.

Specification:

Commodity | Brinell-indention Optical Measurement System |

Model | QB-310 |

Code # | 838-310 |

Measuring Range | 1~750HBW |

Brinell Diameter Size Resolution | 0.0001mm/0.1um |

Hardness Resolution | 0.1HB |

Accuracy of Measurement | ±1%(HBW10/3000) |

Microscope Zoom Range | 0.7~5X |

Camera | 1/2.7”; USB2.0 2MPixel; Pixel Size:3um*3um; 30FPS |

Compatible Indenter | 10mm; 5mm; 2.5mm and 1mm Brinell ball Indenter |

Z Axis Travel | 100mm |

Z Axis Guiding | Manual driven |

Illumination | Adjustable LED surface light illumination |

Software | Brinscan |

Operation OS | Windows Operation System 10 |

Working Environment | Temperature 20℃±1℃, Humidity 30~80% |

Voltage | 220V/50HZ |

Weight | 20Kg |

Dimension | 440x410x700mm |

Software Introduction:

1.HD Image

Microscope applies cold LED light source, high-definition Optical system and CMOS digital camera. Indentation can clearly re-appear in image.

2. Auto-Identification

BrinScan can identify indentation edge automatically, and measuring indentation circle automatically (above 200 points for one circle). It calculates diameter and gets Brinell hardness automatically. For large indentation, the whole indentation need’t show up, more than 1/2 indentation appear on the interface can be measured.

3. One-key Measuring

BrinScan has a simple and generous interface, operator can use without professional training. There is no need to do manual selection, just one key operation, the indentation diameter and hardness value will come out. BrinScan also reserves the basic selection function like Two-point, Three-point, and whole selection. Image magnification can be used in manual measuring, improving manual measuring precision.

4. Easy Calibration

BrinScan initial calibration can be done with glass scale and Brinell standard hardness block. After calibrating a scale (K value), it needn’t do calibration again when the measuring scale is changed, we can directly measure in new scale.

5.Report Output

BrinScan displays indentation diameter, measuring value, Max, Min, conversion value (HRA, HRB,HRC,HV,HS, tensile strength, etc.). Auto saving indentation image, and department and operator can be user defined. Word, Excel can be generated automatically without manual record.

6. Strong Compatibility

BrinScan can be used in connect with any kind of Brinell Hardness Tester, compatible with WIN10 and Win11.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2026 Sinowon | All Rights Reserved.