The PC-200B is a tabletop manual precision sectioning saw. This is a versatile cutting machine designed for sectioning circuit boards and a variety of other sample cutting applications, such as metals, fasteners, rocks and ceramics, polymers, composites, electronics, semiconductors, biomaterials, etc.

◆ Powerful DC motors with high torque

◆ Variable speed. Max speed can be customized

◆ Blade feed: Automatic/manual dual mode

◆ Blade feed movement: linear or pulse

◆ Color touchscreen control panel, easy to use

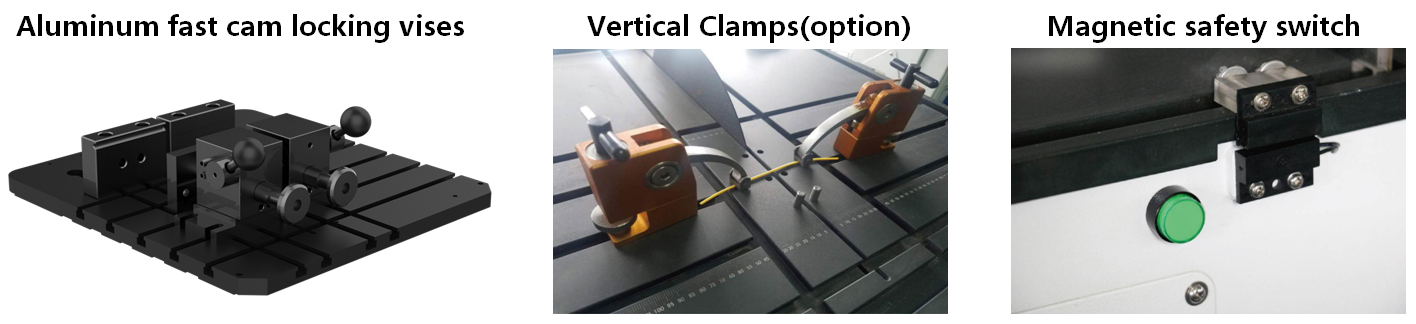

◆ Magnetic safety switch. The blade can stop immediately once the cover is open

◆ Hard anodized aluminum table with T-slots. Easy to change the vises

◆ Aluminum fast cam locking vises (left and right)

◆ Composites support cover by integral molding, anti-rust

◆ Transparent top cover, easy to observe samples

◆ Built-in wheel cooling

Description | AC-200B |

Blade Feed | Automatic/manual |

Blade movement | Continuous, pulse |

Blade(mm) | 200*12.7*0.8 |

Blade speed (rpm) | 500-3000, or customized |

Table Dimensions (WxD,mm) | 368*424 |

DC Motor | 600W |

Power | 110/220V AC, 50-60Hz, 1 Phase |

Copyright © 2018 Sinowon Innovation Metrology Manufacture Limited. | All Rights Reserved 粤ICP备16062806号

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.