efficient material testing equipment design for measuring

1. After many times of iterations, sole weight of material testing equipment 'body frame is effectively decreased.

2. The product is known for its durability. It has been tested under circumstances such as extreme temperatures, contamination, excessive pressures, flow, speeds, and load.

3. Thanks to its great breathability, this product will not result in many skin problems such as blisters, rashes, and infections.

4. Customers who have repurchased it said there is no color fading or paint flaking off problems even it has used for a long time.

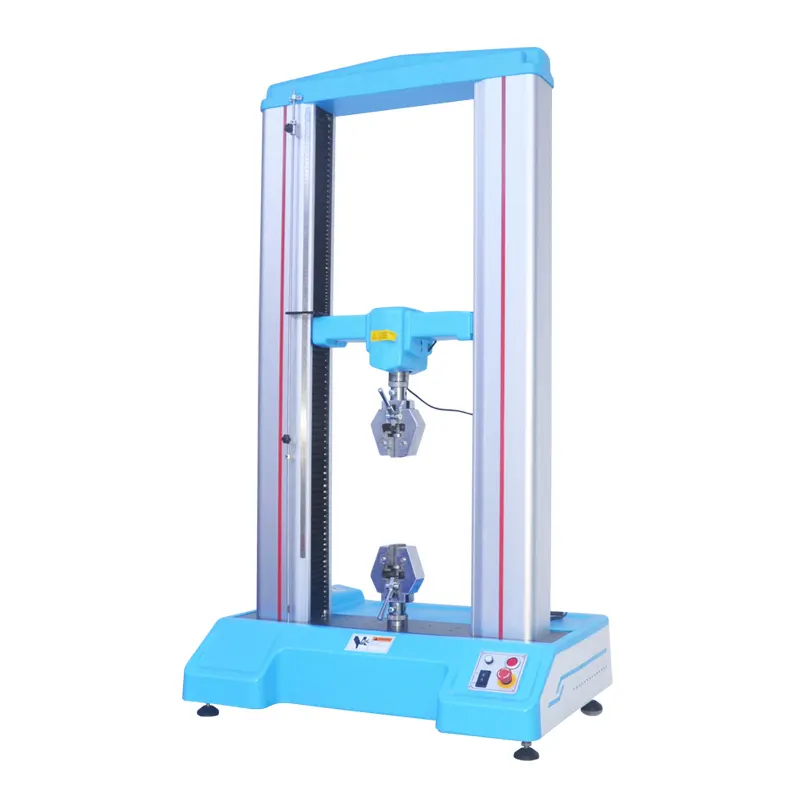

Vexus MT20 series of material testing machine is designed in double-column with maximum testing force 20KN, it is able to make the material testing about tensile, compression, bending, shearing, bonding strength, peeling, tearing, etc, it is applied to test the material such as rubber, plastic, leather, metal, nylon line, fabric, paper, aviation, packaging, construction, petrifaction, electrician, vehicle and other materials.

It is a stable and affordable material testing instruments for the incoming quality control, physical test, mechanics research, material development, etc.

Machine Structure

◆ The material testing is driven by AC servo motor stably;

◆ The linear motion is ensured by double precision ball screw rod smoothly;

◆ The columns are protected by aluminum shell with sandblasted surface perfectly;

◆ The base cover is made of high-grade ABS plastic with spray coating, which is durable and beautiful;

◆ The fine adjustment switch is standard delivery for up and down stroke;

◆ The different functional grips can be replaced by the quick-release-clamp easily.

Specification

| Product Name | Universal Material Testing Machine | ||

| Model | Vexus MT20-700 | Vexus MT20-1000 | Vexus MT20-1500 |

| Test Stroke | 700mm | 1000mm | 1500mm |

| Capacity | 10N, 20N, 50N, 100N, 200N, 500N, 1KN, 2KN, 5KN, 10KN, 20KN(can select double capacities preparation) | ||

| Display | Computer display mode | ||

| Force Resolution | 1/500,000 | ||

| Force Accuracy | ≤±0.3% | ||

| Stroke Resolution | 0.005mm | ||

| Control Mode | All computerized operation mode | ||

| Test Width | Ø420mm | ||

| Test Speed | 0.1~1000mm/min, can set by computer, with up & down fast adjustment button of grips | ||

| Force Unit Switch | Kgf, N, Ibf, g, ton, Mpa | ||

| Stop Mode | Overload stop, emergency stop button, specimen damage automatic stop, upper & lower limit set automatic stop, automatic reset function | ||

| Machine Dimension | 72×52×130cm(W×D×H) | ||

| Machine Drive | Servo motor drive, synchronous wheel and precision ball screw drive | ||

| Power | 400W | ||

| Machine Weight | Approx 115kg | ||

| Power Supply | 220V 50/60HZ 10A | ||

| Standard Device | 1 set of grips, computer software, USB computer connection wire | ||

| Optional | Computer and Grips | ||

MS100 is professional software for material testing in windows system, it is able to conduct tensile, compression, bending, shearing, bonding strength, peeling, tearing and other tests for rubber, plastic, leather, metal, nylon line, fabric, paper, aviation, packaging, construction, petrifaction, electrician, vehicle and other materials.

Measure Software Features

◆ MS100 Test & Control System is designed to work PC Electronic Universal Testing Machines, PC Hydraulic Universal Testing Machines and PC Compression testers, which can make the testing of tensile, compression, bending, shearing, tearing and peeling test, etc.

◆ MS100 has the functions of data collection, save, processing and printing test result, it can calculate max force, yield strength, average peeling force, max deformation, yield point, elastic modulus and other parameters; can conduct curve graphics processing, multi-sensor support, flexible data processing, MS-ACCESS database support, and so on.

Company Features

1. As one of the most well-known exporter, Sinowon Innovation Metrology Manufacture Limited. is going to increase its capacity and grow stronger.

2. Every piece of material testing equipment has to go through material checking, double QC checking and etc.

3. Sinowon Innovation Metrology Manufacture Limited. supports customized service for the production line. Inquire now! Stimulating innovation dynamism also is an important part in the culture of Sinowon. Inquire now! Striving to be a leader in the international universal testing machine industry is our ultimate goal. Inquire now! Sinowon Innovation Metrology Manufacture Limited. endeavors to exceed our customer's expectation for our products. Inquire now!

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.