elegant metallographic equipment factory for medical devices

1. Sinowon grinding and polishing equipment has undergone a series of examination procedures to check on the colorfastness of fabrics, the cleanness of sewing threads, and accessories safety. Its quality and accuracy are improved every year

2. The product is a perfect fit for most people. It improves wearing comfort and contributes significantly towards maintaining healthy feet. It is up to both domestic and international standards

3. To ensure the quality, it will be fully tested by our professional staff. More than 10,000 pcs have been delivered and installed

Product Feature

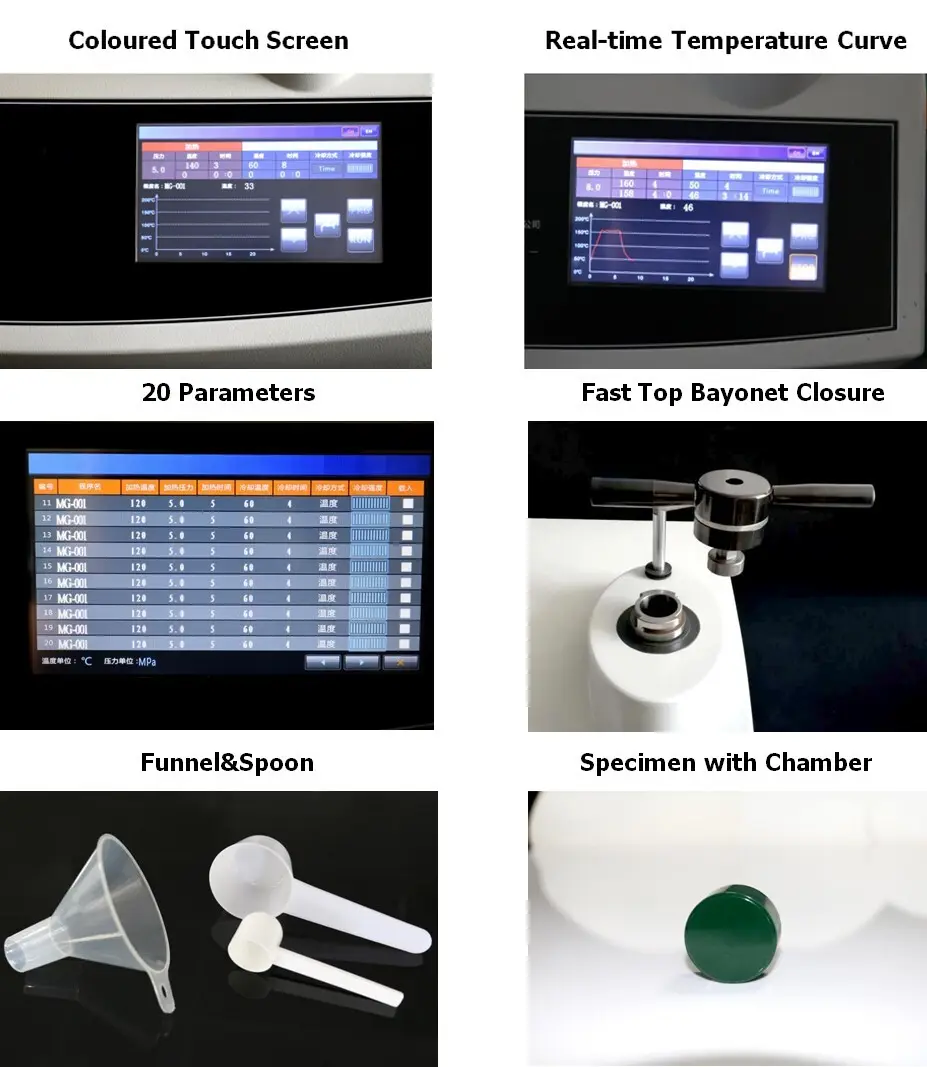

◆ Easy to use. One button start, automatic pressure loading, heating and cooling;

◆ High efficiency. New design of heating and cooling units significantly reduce the cycle time. Usually, the cycle time for 30mm diameter specimen is about 8 minutes;

◆ The two cylinders can work independently and have different mold size;

◆ User-friendly operation interface. Coloured HMI touch screen allows the users to set pressure, heating temperature, heatingtime and cooling time easily;

◆ Real-time temperature curve display;

◆ 10 memory modes which can set and save the parameters;

◆ For one cylinder, two specimens can be produced simultaneously with the use of a spacer;

◆ Three cooling modes: time, temperature, manual. It also has water-saving function;

◆ The cover is made of high temperature resistant composites by integral molding;

◆ Mobile plastic recirculation coolant tank is optional.

Specification

Description | AMP 5D | AMP 6D | AMP 7D | AMP 8D |

Operation | Automatic | |||

Pressure | Air | Air | Hydraulic | Hydraulic |

Cooling | Automatic/manual | |||

Mold | ○25 ●30 ○40 ○50mm, others can be customized | |||

Max Force(kgs) | 300 | 500 | 1200 | 4000 |

Max Tem(℃) | 180 | 180 | 200 | 200 |

Heater | 1.2KW | 2.4KW | 2.4KW | 3KW |

Dimension(WxDxH) | 600x560x430 | 600x560x430 | 540x560x430 | 540x560x430 |

Weight | 45Kg | 45Kg | 65Kg | 77Kg |

Power | 220V50Hz | |||

Air source | Need | Need | ||

Cooling Water | Need | |||

Mold Release | ○ | ○ | ○ | ○ |

Black Resin | ● | ● | ● | ● |

Green Resin | ○ | ○ | ○ | ○ |

Red Resin | ○ | ○ | ○ | ○ |

Conductive Resin | ○ | ○ | ○ | ○ |

Edge-protection Resin | ○ | ○ | ○ | ○ |

Transparent Resin | ○ | ○ | ○ | ○ |

Air filter | ● | ● | ● | ● |

Funnel&Spoon | ● | ● | ● | ● |

Drains | ● | ● | ● | ● |

●Standard○Option

Details

Company Features

1. Sinowon Innovation Metrology Manufacture Limited. has built up long-term cooperation with many large metallographic equipment factories. Sinowon Innovation Metrology Manufacture Limited. has a strong and complete production capacity.

2. Sinowon pays a lot of attention to the quality of metallurgical equipment .

3. Sinowon Innovation Metrology Manufacture Limited. has a comprehensive professional production equipment and sophisticated production team. You will be satisfied with our highest quality polishing equipment. Get more info!

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.