How many people in Sinowon QC team?1

There are several professionals in the QC team of Sinowon Innovation Metrology Manufacture Limited.. They are responsible for the whole process production, from in-material test, semi-finished product test, finished-product quality test, and test before packaging and after packaging. They are a team well organized for each step. Every time you see along the production line, they would be there. In addition, they are equipped with advanced testing and monitoring devices. The combination of manual test and automated monitoring ensures that the pass rate of our product could reach over 99 percent.

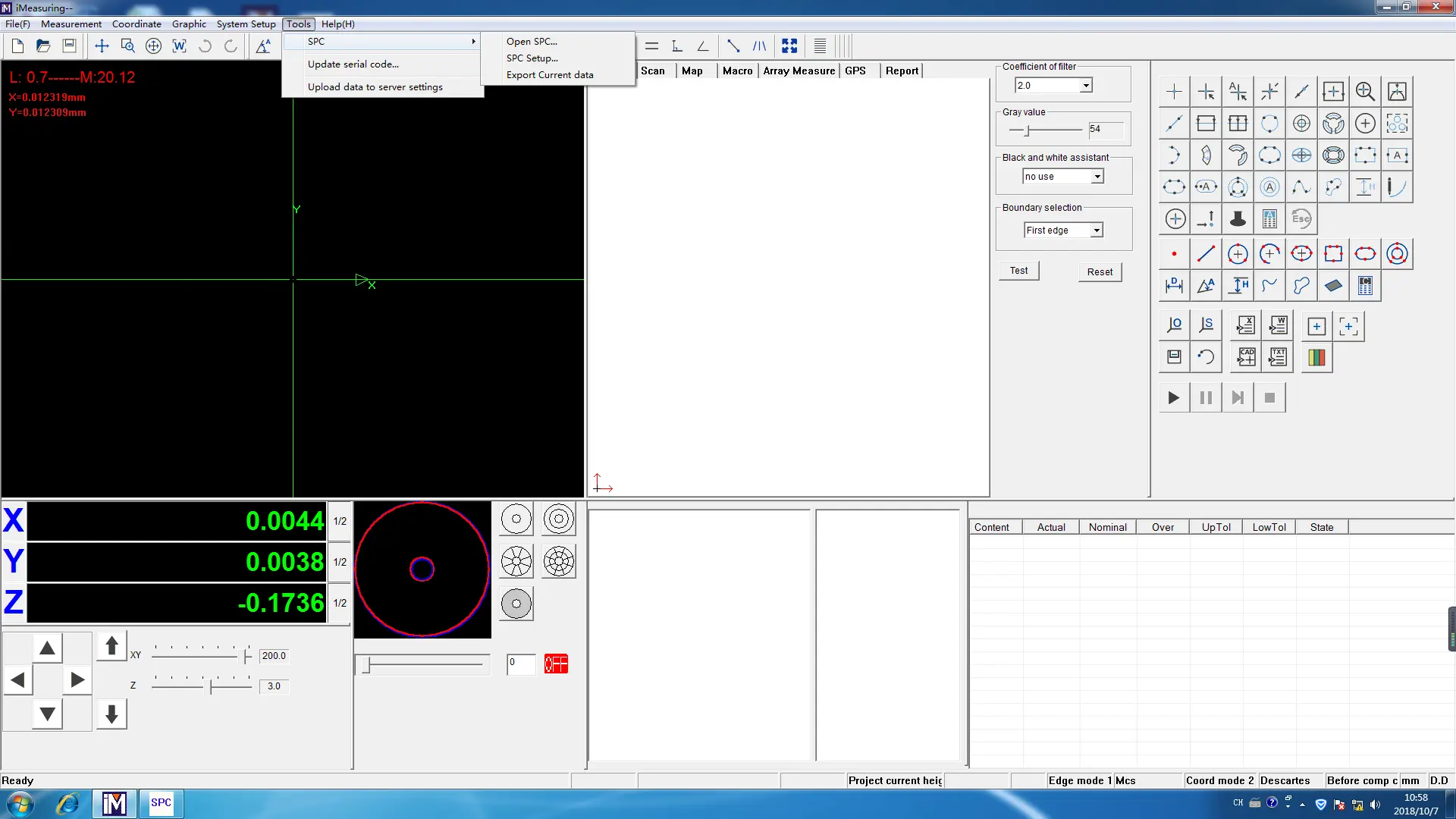

Sinowon is a trustworthy company based in China. We have accumulated rich experience in the development, manufacture, and marketing of industrial microscope. As one of Sinowon's multiple product series, instant measurement system series enjoy a relatively high recognition in the market. Sinowon Optical Measuring Projector is produced based on various theories. It adopts the heat management theory to check and make sure the optimized working temperature for the battery cells. It can be customized according to customers' needs. The strong economic strength of our team allows to carry out strict quality assurance. The product is verified by ISO9001:2015 to be quality ensured.

We continuously seek to improve our operating performance with an emphasis on health, safety, security, and environment, as well as adhering to our ethics and compliance principles. Get quote!

Hydraulic universal testing machines have very high accuracy requirements.

The hydraulic system is the power drive mechanism of the tensile testing machine.

The specific application of the electronic universal testing machine in the automobile manufacturing process: The electronic universal testing machine needs to be used for automobile parts.

Wave soldering refers to the molten solder (lead-tin alloy), sprayed by electric pump or electromagnetic pump into the solder wave required by the design, can also be formed by injecting nitrogen into the solder pool, so that it is pre-loaded The printed board of the component realizes the soft soldering of the mechanical and electrical connection between the solder end or the pin of the component and the pad of the printed board through the solder wave.

The frequency converter is a power control equipment that uses frequency conversion technology and microelectronics technology to control AC motors by changing the frequency of the motor's working power supply.

Electronic universal testing machine is a necessary equipment to control the quality of products.

The calibration operation of the electronic universal testing machine is still relatively unfamiliar to friends who use it for the first time.

Selective wave soldering defects and their prevention.

Testing machine, broadly speaking, is an instrument that verifies the quality or performance of a product or material according to the design requirements before it is put into use.

The tensile force is not an accurate value after being measured by the testing machine, and subsequent calculations are required to get the desired value.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.