Is coordinate measuring machine cmm training tested before shipment?

Yes, we ensure sufficient inspection of the finished products before they are shipped out of the factory. Sinowon Innovation Metrology Manufacture Limited. has been focusing on the manufacturing of measuring machine for years. We are proficient in conducting quality control methods, including appearance inspection, tests on product performance, and functionality inspections. There is a quality control team arranged for product quality enhancement. Once there are defectives found, they will be removed to increase the pass rate. If you are interested in our quality control process, please contact us to apply for a factory visit.

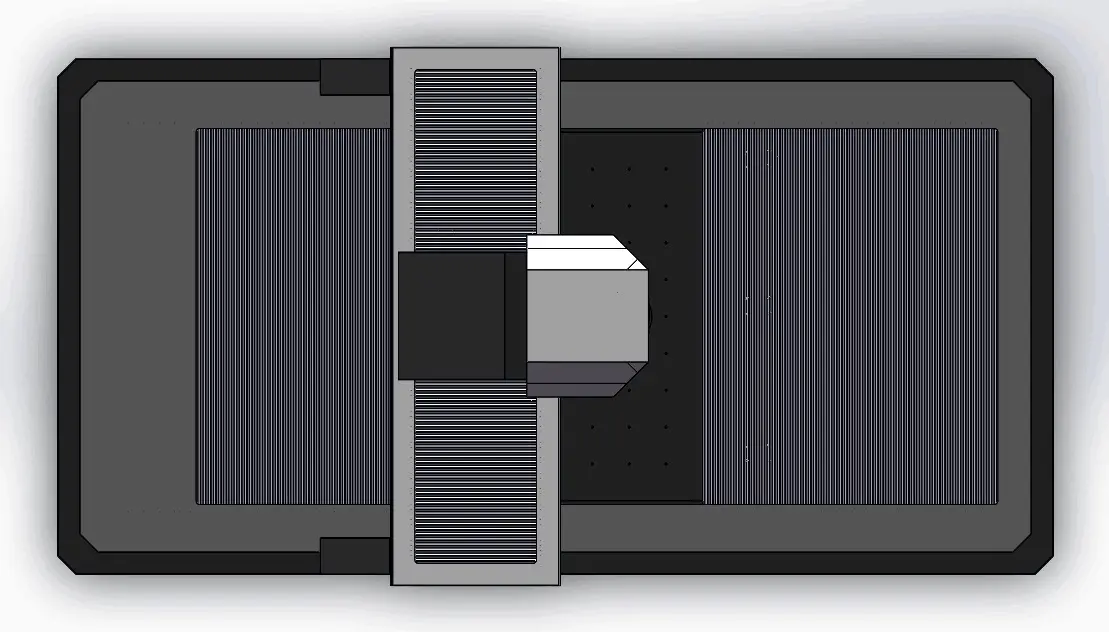

In the past years, Sinowon has developed from a small manufacturer of visual inspection system to a global and diversified provider in the industry. The rockwell hardness tester for sale is one of the main products of Sinowon. The quality of Sinowon tools maker microscope can be guaranteed. It is sent to the reputable third-party quality testing institution which offers certification services for pool and spa component manufacturers in a variety. It can be customized according to customers' needs. With the advantages of material testing machines, material testing equipment is rather powerful in the similar products. The Gost certificate has been obtained for the Russian market.

Above and beyond the product needs, we strive to establish global logistics and support network to continuously deliver the extra services customers require to make their projects a success. Get quote!

Hydraulic universal testing machines have very high accuracy requirements.

The hydraulic system is the power drive mechanism of the tensile testing machine.

The specific application of the electronic universal testing machine in the automobile manufacturing process: The electronic universal testing machine needs to be used for automobile parts.

Wave soldering refers to the molten solder (lead-tin alloy), sprayed by electric pump or electromagnetic pump into the solder wave required by the design, can also be formed by injecting nitrogen into the solder pool, so that it is pre-loaded The printed board of the component realizes the soft soldering of the mechanical and electrical connection between the solder end or the pin of the component and the pad of the printed board through the solder wave.

The frequency converter is a power control equipment that uses frequency conversion technology and microelectronics technology to control AC motors by changing the frequency of the motor's working power supply.

Electronic universal testing machine is a necessary equipment to control the quality of products.

The calibration operation of the electronic universal testing machine is still relatively unfamiliar to friends who use it for the first time.

Selective wave soldering defects and their prevention.

Testing machine, broadly speaking, is an instrument that verifies the quality or performance of a product or material according to the design requirements before it is put into use.

The tensile force is not an accurate value after being measured by the testing machine, and subsequent calculations are required to get the desired value.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.