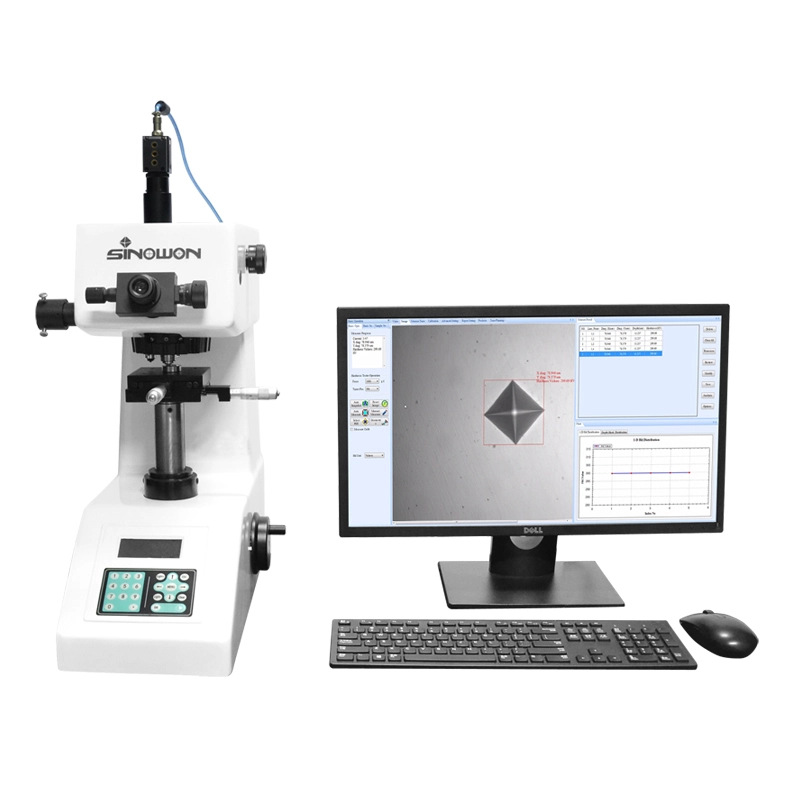

Manual Micro Vickers Hardness Tester

Characteristics

● The micro hardness testing of materials allows for the determination of the hardness of small or thin specimens and small areas of larger specimens, Micro hardness testing is commonly used to determine characteristics of thin sheets, foils, fine wire, epoxies, paints, etc. and is often employed in R&D applications.

● Micro hardness is especially useful in determining hardness variations, caused by hardening, quenching, plating, fabrication, welding or annealing, bonding, etc. Micro hardness testing can be accurately employed using loads as slight as 10 grams, somewhat less and considerably more in certain situation.

●Optional Vickers hardness testing software is available for CDH( Carburized layer depth)measurement.

Application Range

◆ Testing very thin materials like foils, thin pieces, coatings layers, etc;

◆ Measuring hardness of the surface of a part, small parts or small areas;

◆ Measuring individual micro-structures;

◆ Measuring the depth of case hardening by sectioning a part and making a series of indentations to describe a profile of the change in hardness.

Specification

Commodity | Manual-Turret Micro Vickers Hardness Tester | Auto-Turret Micro Vickers Hardness Tester | |

Model | HV-1000 | HV-1000Z | |

Code# | 823-101 | 823-101Z | |

Hardness Scale | HV | ||

Hardness Conversion | HV, HR, HRC, HB, HK | ||

Loading Force | N | 0.098、0.246、0.49、0.98、1.96、2.94、4.90、9.80 | |

gf | 10、25、50、100、200、300、500、1000 | ||

Indentation Measurement | Analogue Eyepiece with Mechanic Micrometer | ||

(To measure the indention by optional Vickers Testing Software system) | |||

Loading Control | Automatic (Loading, Dwell, Unloading) | ||

Magnification of Microscope | Observation:10x/40x; Measurement:10x/40x | ||

Magnification on of Eyepiece | 10x Analogue Eyepiece | ||

Dwell Time | Adjustable 5~60s | ||

Testing Range | 1HV~3000HV | ||

Analogue X-Y Anvil | Size:100x100mm; Travel:25 x25mm; Resolution: 0.25um | ||

Optical Channel | Two-Channel: Eyepiece/camera switchable | ||

Illumination | Adjustable Halogen light-source | ||

Max. Height of Specimen | 90mm | ||

Instrument Throat | 120mm | ||

Operating Temperature | 23±5℃ | ||

Operating Humidity | <65% | ||

Power Supply | AC220V/50Hz; AC110V/60Hz | ||

Dimension (LxWxH) | 530×290×490mm | ||

Gross/Net Weight | 50Kg/40Kg | ||

Standard Delivery

Commodity | Code # | Commodity | Code # | Commodity | Code # |

MicroVickers Intender | 823-401 | 10x Analogue Eyepiece | 823-301 | Dust Cover | 823-911 |

X-Y Working Stage | 823-701 | 10x Objective | 823-311 | Toolbox | 823-901 |

Hardness Block (700~800) HV1 | 823-611 | 40x Objective | 823-341 | Power Cord | 823-801 |

Flat Precision Clamp | 823-711 | Thin-Piece Clamp | 823-751 | Filament Clamp | 823-761 |

Hardness Block (400~500) HV0.2 | 823-621 | Warranty Card / Qualified Certificate/ Operation Manual / Packing List | HV-1000 | Flat Precision Clamp | 823-711 |

Standard Delivery

Commodity | Code # | Commodity | Code # | Commodity | Code # |

Digital Micrometer Head | 823-719 | Unequal Specimen Clamp | 823-741 | Dell PC System | Dell3070MT |

Camera Adapter | 823-361 | USB CMOS Camera | 823-471 | Vickers Measuring Software | iVicky 2.0 |

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.