series vision computer factory for precision industry

- Sinowon persists in the principle of 'users are teachers, peers are the examples'. We have a group of efficient and professional personnel to provide high-quality services for customers.

1. Sinowon vision computer software is produced at the same location and on the same equipment, which ensures consistency over large runs and multiple orders.

2. The product cushions the impact force caused by the foot's collision with the ground. The materials mainly EVA, PU, or silica gel used in it has excellent buffering performance.

3. The product features stable performance. The electrical leakage risks have been eliminated, ensuring that it can work under low leakage rates.

4. With its high-quality products, perfect services and sincere cooperation, Sinowon Innovation Metrology Manufacture Limited. has established a leading position in the industry.

5. Sinowon is the preferred brand in vision computer industry.

Introduction

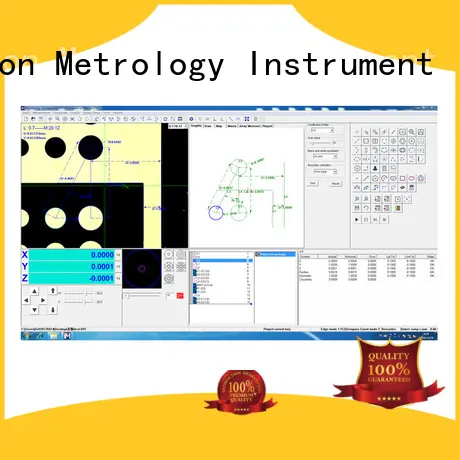

iMeasuring software is a professional multi-sensor measuring software which combined with the developers ten years experience in the measuring and software research industry The design principle is a friendly operation, powerful function, high accuracy and stability, simple maintenance.

Characteristic

l Excellent software architecture design and fully object-oriented, to ensure the software is stable and reliable.

l Support with multiple languages, no need to install a language pack and change the software which is convenient for local customers.

l Professional SPC statistical analysis software connected to measuring software, to realize that the data could automatically export to SPC database without manual operation.

l The same model of software will be permanently free to update, it can help to reduce other trouble to the customer.

l With powerful edge finder algorithm, which can help to get the edge of the shadow or dark image and ensure high accuracy.

l The software could automatically recognize and measure line, circle, arc, and other elements.

l It is based on different elements and supplies multiple element construction functions such as Translation, rotation, extraction, combinations, parallel, vertical, mirroring, symmetry, intersection, tangent, etc.

l The software can show you different intelligent processing functions such as ultra limit red alert, ultra-limit

pause, failure measuring pause, manual measurement, skip running, forced running, etc.

l The measuring data can auto export to TXT, WORD, EXCEL and SPC software database without the third

party software conversion and manual operation.

l The software has breakpoint setting function, it can be intelligent switched between manual measurement and auto measurement.

l The software can import “cancel” and “Recover” to make it easier and faster to operate.

l It can easily measure flatness quickly with powerful laser measuring function, and test the small bumps, pits, V-angle and high-precision surface scanning while video and probe cannot test it.

l The software can supply auxiliary light-dimmer indicated function to avoid measuring error caused by light intensity problem and improve measuring accuracy and efficiency.

l The software can input viewport navigation, to be convenient to position and get a test place by clicking middle key.

l The software can supply many function such as accurate focus, quick focus, image height measurement, and the repeatability can reach to 3um(above 2x magnification ).

l The software can easily and quickly import and export DXF file and set up coordinate system for auto measurement.

l The software supply multiple running control mode, which make it faster and convenient to position.1.Operate handle; 2. Click middle key in the image window, long-press right key; 3. Click middle key in the drawing window; 4. Move element list window to the primitive; 5. Click the mouse in the running control window; 6. Click middle key in the scan window; 7. Click middle key in the map window; 8. Input coordinate value.

l The image window and drawing window can display the measured elements and marking 2D dimension, which get the result directly.

l The software supply multiple system error correction function, such as: Linear compensation, sector compensation, vertical error compensation, Z axis linear error compensation, lens center offset error

compensation, to ensure accuracy can reach to 0.002mm any place in the XY area.

l The software can photograph mosaic the work piece to get a large map, then marke and measure it.

l The software can support to add simple probe based on the video measurement, to realize 3D measurement.

l The software can auto calculate and mark the present magnification and video magnification, and display the pixel measurement value.

Company Features

1. As a technologically advanced company, Sinowon Innovation Metrology Manufacture Limited. has an advantage in quality.

2. To satisfy the needs of technical innovation in this society, our experienced team has been researching and developing vision computer persistently.

3. We can provide an abundance of linear scale with high quality. Please contact. We are committed to consistently promoting our brand in the communication and marketing of all audiences – connecting customer needs and stakeholder expectations, and building a belief in our future and value. Please contact. Although there are ups and downs, what remains unchanged is Sinowon Innovation Metrology Manufacture Limited. 's pioneering spirit. Customers are bound to find something interesting at Sinowon Metrology Instrument.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Copyright © 2025 Sinowon | All Rights Reserved.