Sinowon bench grinder polishing wheel design for electronic industry

1. Sinowon 6 inch polishing wheel for bench grinder is developed professionally by our R&D team who have many years of experience in the battery industry. Parameters such as electrolyte types, metal ingredients, and battery cells have been considered respectively. A team of experienced talents is gathered to support the product sales

2. This piece of furniture is functional and among timeless pieces that can easily fit in a space and also people's budget. The product is well known for high accuracy and great stability

3. The product is tested by our quality experts in strict accordance with a range of parameters to ensure its quality and performance. The product is well used in many large engineering projects

The AC-300 series are floor standing automatic cutters with high performance. This is a versatile cutting machine designed for sectioning an extremely wide range of materials, such as metals, fasteners, rocks and ceramics, polymers, composites, electronics, semiconductors, biomaterials, etc. The machine integrates the optimized precision cutting technology with advanced control system to provide excellent cut quality and high throughput.

Product Feature

◆ Powerful motor to reduce cutting time and provide high productivity

◆ Smart feed. The machine can adjust the feed speed in real time with the load changes

◆ Cutting modes: Y-continuous, Y-pulse, Z-continuous, Z-pulse, slicing (different model, different cutting mode)

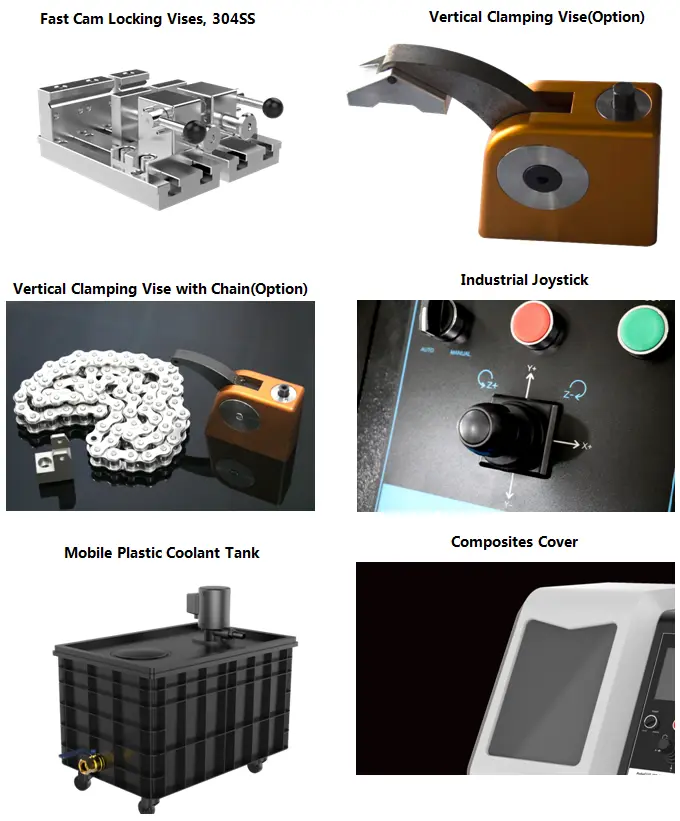

◆ Versatile industrial joystick with X, Y, Z axis. Easy to use

◆ 8 inch color touchscreen for simple operation and user friendliness

◆ Electrical brake for faster stopping of the blade

◆ Chamber illumination with LED

◆ Aluminum casting base, powder coated

◆ T-slot Table made of stainless and aluminum alloy

◆ Fast Cam Locking Vises, made of 304 stainless steel

◆ Left cover made of composites by integral molding

◆ Mobile plastic recirculation coolant tank

◆ Independent pump for cleaning the chamber

◆ Optional laser alignment aid

Specification

Description | AC-300XYZ | AC-300YZ | AC-300Z |

Y Feed | Automatic | ||

Z Feed | Automatic | Automatic | --- |

X Feed | Automatic | ○Manual | ○Automatic○Manual |

Cutting mode | Continuous, Pulse | Continuous, Pulse | Continuous, Pulse |

Blade(mm) | 300*32*1.8 | ||

Blade speed (rpm) | 500-3000 | ||

Table Dimensions (WxD,mm) | 350*260 | ||

X Travel | 80mm | ||

Cooling | Automatic/manual | ||

Main Motor | 3.0KW | ||

Power | 110/220V AC, 50-60Hz, 1 Phase/3 Phase | ||

Accessories | |||

Diamond Blade | ○ | ○ | ○ |

SiC blade | ○ | ○ | ○ |

Alumina Blade | ● | ● | ● |

Fast Cam Locking Vises | ● | ● | ● |

Vertical Clamping vise | ○ | ○ | ○ |

Laser alignment aid | ○ | ○ | ○ |

Plastic tank | ● | ● | ● |

Plastic tank with magnetic filter | ○ | ○ | ○ |

Cutting fluid | ○ | ○ | ○ |

Centrifugal separator | ○ | ○ | ○ |

●Standard○Option

Details

Company Features

1. Sinowon Innovation Metrology Manufacture Limited. is an expert maker of a wide range of various bench grinder polishing wheel . We expect no complaints of used metallurgical equipment from our customers.

2. Our professional equipment allows us to fabricate such 6 inch polishing wheel for bench grinder .

3. Always aim high in quality of precision cutting . Sinowon Innovation Metrology Manufacture Limited. seek commonality in R&D while preserving differences with customers. Get info!

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.