Sinowon sturdy Automatic vision measuring machine personalized for gear

SU-400 Dynasonic Hardness Tester is a universal portable durometerwith twin—testing-method. It applies twin-method aboutstate ultrasonic contact independence: UCIand dynamic rebound: Leebto make hardness testing in one instrument, it solves the dilemma that Leeb method can not test the hardness of plating and coating(in UCI), and UCI method can not test the coarse crystal material in the casting industry(in Leeb).

SU-400 can not only work with the UCI motorized and manual probes, but also work with theLeeb impact probe, it is universal to test the hardness of material with the fine crystalstructure or coarse crystal structure in the metal industry.

SU-400 UCI probe system is perfect to measure hardness testing about the coating and plating, which can measure the hardness of chrome, copper plating, carburized layer and Nitriding layer effectively.

SU-400 dynamic Leeb probe system is suitable to measure hardness of coarse material, such as, casting and forging

SU-400 is a NDT durometer due to the contact indention is too small to observe, it is one of the excellent solution to test hardness of finished products, such as, the mold, gear, shaft, rod, screw, rails, etc.

SU-400 conforms the standard ASTM A1038-2005, DIN standard DIN50159-1-2008 and China National standard GB/T 34205-2017, GB/T 17394.

PRODUCT Feature

◆ One instrument two applications—Support ultrasonic probe and Leeb impact device.

◆ Metal shell—Metallic texture, shield electromagnetic interference effectively, improve instrument stability.

◆ Color screen display—Display the current measurement value, accumulative measurement value, Max, Min and Ave value.

◆ Bluetooth transferring—Support wireless Bluetooth print and data transferring.

◆ Mass storage—Save 1000 groups data.

◆ Calibration access—Save 20 groups calibration data without doing calibration for the same material over and over.

Specification

| Product Name | Dynasonic Hardness Tester | ||||

| Model | SU-400 | ||||

| Code# | 882-151 | ||||

| Ultrasonic Probe | Standard delivery:2Kgf(optional Manual 1Kgf、5Kgf、10Kgf,motorized 0.3Kg and 1Kgf) | ||||

| Impact Devices | Standard delivery:D(optional DC,DL,D+15,C, G) | ||||

| Hardness Scales | Vickers(HV);Rockwell C(HRC); Rockwell A(HRA); RockwellB(HRB);Brinell(HB) | ||||

| Measuring Range | HV:50~1599; HRC:20~68; HB:76~650;HRB:41~105; HLD:170~960; | ||||

| Measuring Accuracy | HV:±3%HV; HRC:±1.5HRC; HB:±3%HB;HL: ±8HL | ||||

| Resolution | 0.1HR, 1HV, 1HB, 1HLD,0.1HS | ||||

| Result Display | Measurement value, Max, Min, Ave, single mode, batch mode, etc. | ||||

| Data Storage | 1000 group test results and 20 group calibration data | ||||

| Data Transfer | Bluetooth | ||||

| Continuous Working Period | 10h (turn off the back light) | ||||

| Working Environment | Temperature: -10°C to 50°C Humidity :30%-80% R.H. | ||||

| Battery Voltage | 4.2V | ||||

| Charge Mode | USB | ||||

| Dimension | 160x80x31mm | ||||

| Weight | ≤500g(probe not included) | ||||

Standard Delivery:

Product Name | Code # | Product Name | Code # | Product Name | Code # |

Instrument Main Body | 882-151 | Rockwell Hardness Block | 882-611 | Accessories Box | 882-901 |

2Kg Manual Probe HP-2K | 882-321 | Leeb Hardness Block | 882-630 | USB Cable | 882-851 |

Impact Devices Type D | 882-410 | Probe Cable | 882-801 | Operation Manual | SU-400 |

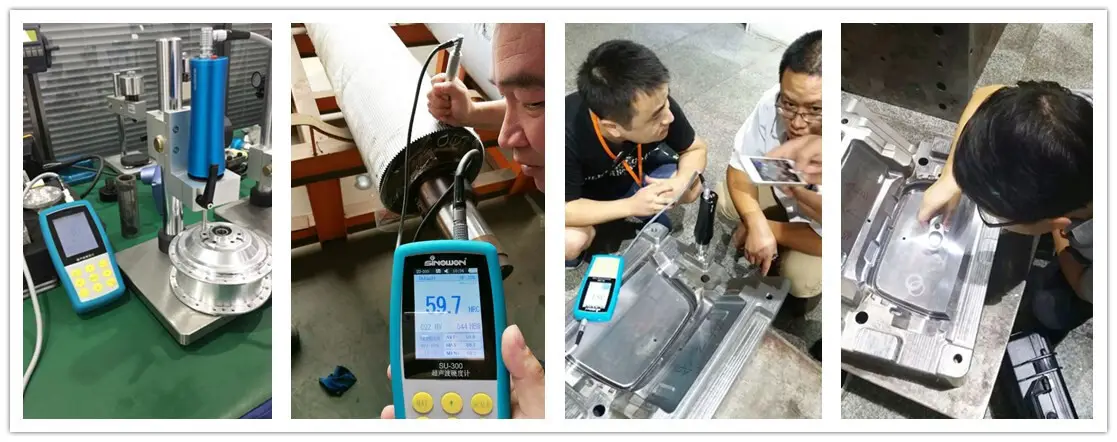

Application

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.