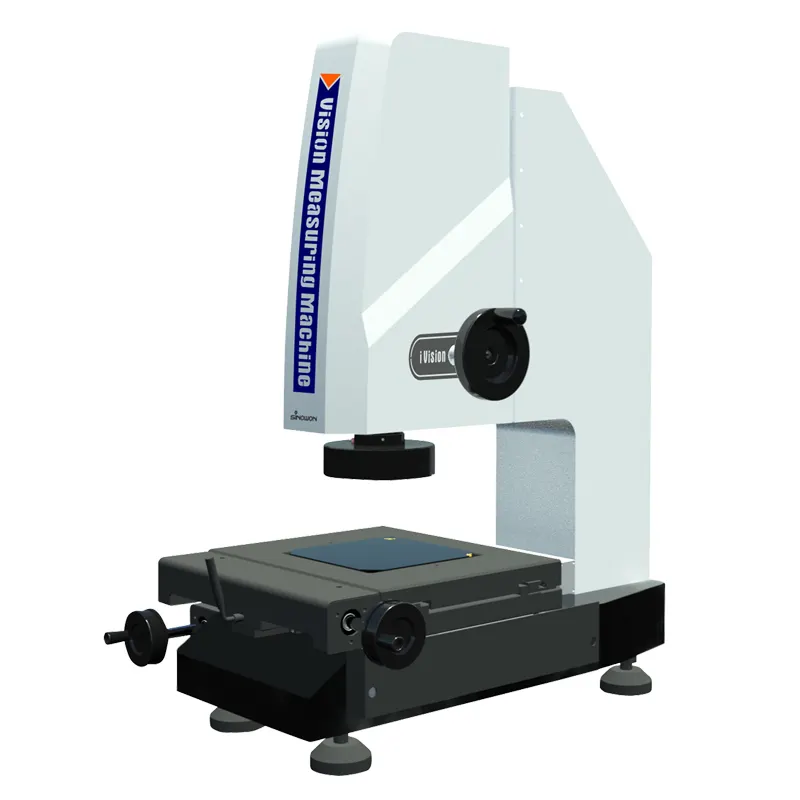

Sinowon visual measurement design for PCB

Brief Induction:

IMS-1010 is the 2D vision measuring machines with optical detent zoom lens for the measurement of geometric dimension and tolerance, it is movable by the light weight: 35Kg and small size: 498x382x627mm, and it is widely applied at the industry of 3C, semiconductor, PCB, automobile parts, medical parts, precise molds, etc.

Product Characteristic:

l IMS-100 is able to be moved in different workshop and laboratory by the mall size and light weight easily;

l High precision toothless rod and fast moving locking device ensures repeatability error is less than 2um;

l High precise working stage with 0.5um optical linear scales ensures the accuracy is less than 2.5+L/200um;

l High definitive detent zoom lens and high resolution color camera ensures clear image without distortion;

l With programmable surface 4-ring 8-division LED Cold Illumination and contour LED telecentric illumination and built-in intelligent light adjustment, it can automatic control the brightness in the 4-ring 8-division;

l Powerful function iMeasuring 2.0 Measuring Software, highly enhance the quality control, and it can output Word, Excel, PDF, TXT report and AutoCAD file automatically.

Technical Specifications

Commodity | 2D Movable Manual Vision Measuring Machine | ||||||

Model | iMS-1010B | ||||||

Code# | 521-110B | ||||||

Metal Table | 250x208 mm | ||||||

Glass Table | 130x130 mm | ||||||

X/Y Travel | 100x100 mm | ||||||

Z-axis Travel | 100 mm | ||||||

X/Y Linear Scale | High Accuracy A-grade linear scale, Resolution: 0.5um | ||||||

Workstage | Precision rails, toothless rod and fast-moving locking device | ||||||

Base and Pillar | High Accuracy Marble Base, Cast Aluminum Pillar | ||||||

Accuracy | E1xy≤2.4+L/200(um) | ||||||

Repeatability | 2um | ||||||

Vision System | USB CMOS Digital Camera | ||||||

6.5x High Resolution Optical Detent Zoom Lens | |||||||

Magnification:0.7X~4.5X; Video Magnification:26X~172X | |||||||

Illumination System (Software Adjustment) | Surface: Adjustable 4-ring 8-division LED Cold Illumination | ||||||

Contour: LED Illumination | |||||||

Zoom Lens | Optical Magnification | 0.7x | 1x | 2.0x | 3.0x | 4x | 4.5x |

Video Magnification | 26.75x | 38.21x | 76.43x | 114.64x | 152.86x | 171.96x | |

Vision field | 8.77x7.1x5.3 | 7.64x6.1x4.6 | 3.92x3.1x2.3 | 2.66x2.1x1.6 | 1.87x1.5x1.1 | 1.53x1.2x0.9 | |

Working Environment | Temperature:19°~24°C | ||||||

Humidity:45% ~75%RH | |||||||

Vibration<0.002g, <15Hz | |||||||

Measuring Software | iMeasuring 2.0 Measuring Software | ||||||

Load Capacity | 5Kg | ||||||

Operation System | Support XP, WIN7, WIN8.1 ,WIN 10, 32/64 operating system | ||||||

Language | English, Simplified Chinese, Traditional Chinese | ||||||

Power Supply | 220V/50Hz/10A | ||||||

Dimension(W*D*H) | 498x382x627mm | ||||||

Net Weight | 35 Kg | ||||||

Description:

l L is measuring length (mm) the mechanical accuracy of Z-axis and focus accuracy is greatly related to the surface of the workpiece.

l **Magnification is approximate value, it is related to the dimension of monitor and resolution.

l 0.5X or 2X objective is optional available, and realize image magnification: 13X~86X or 52X~344X.

l Field of view (mm) = (diagonal*Horizontal*Vertical).

l Executive Standard:GB/T 6830-2013;ISO 10360-7:2011;JJF 1093-2015.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.