approved metallographic equipment factory for medical devices1

Product Feature

◆ Easy to use. One button start, automatic pressure loading, heating and cooling;

◆ High efficiency. New design of heating and cooling units significantly reduce the cycle time. Usually, the cycle time for 30mm diameter specimen is about 8 minutes;

◆ The two cylinders can work independently and have different mold size;

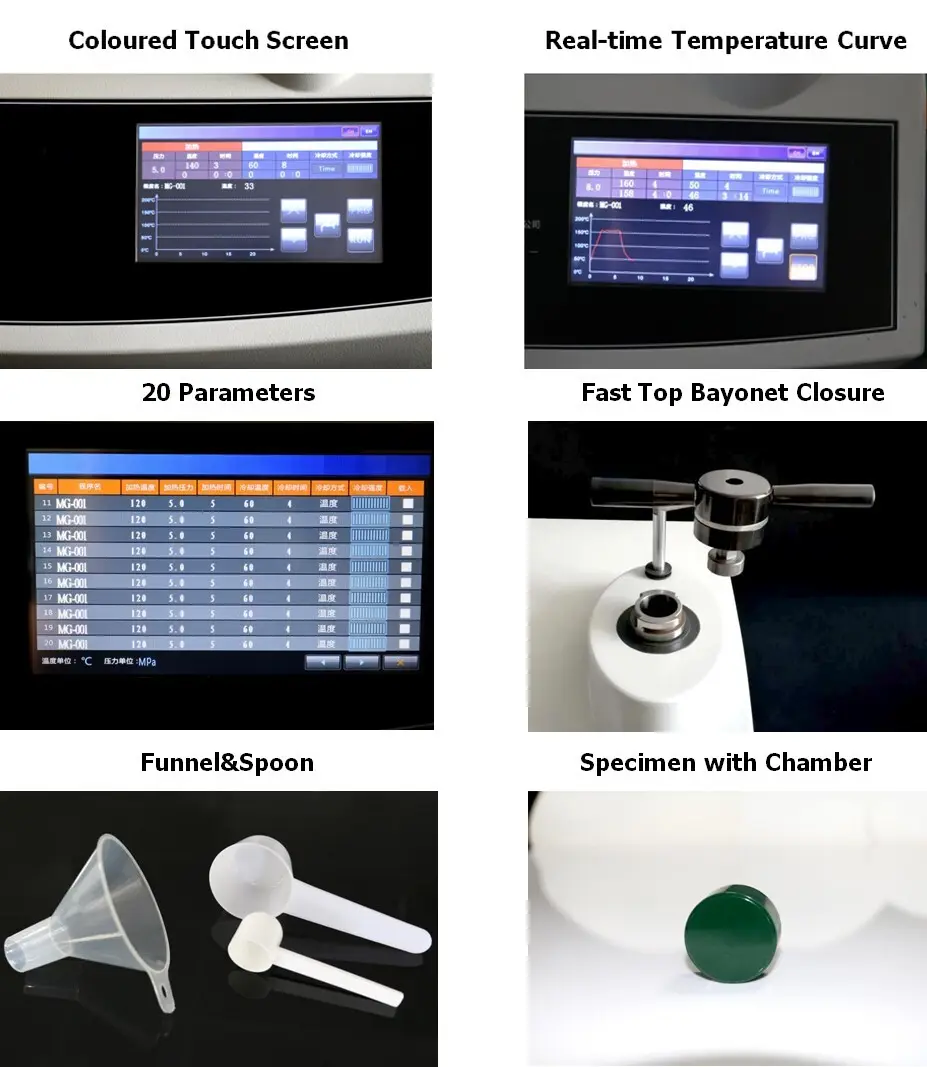

◆ User-friendly operation interface. Coloured HMI touch screen allows the users to set pressure, heating temperature, heatingtime and cooling time easily;

◆ Real-time temperature curve display;

◆ 10 memory modes which can set and save the parameters;

◆ For one cylinder, two specimens can be produced simultaneously with the use of a spacer;

◆ Three cooling modes: time, temperature, manual. It also has water-saving function;

◆ The cover is made of high temperature resistant composites by integral molding;

◆ Mobile plastic recirculation coolant tank is optional.

Specification

Description | AMP 5D | AMP 6D | AMP 7D | AMP 8D |

Operation | Automatic | |||

Pressure | Air | Air | Hydraulic | Hydraulic |

Cooling | Automatic/manual | |||

Mold | ○25 ●30 ○40 ○50mm, others can be customized | |||

Max Force(kgs) | 300 | 500 | 1200 | 4000 |

Max Tem(℃) | 180 | 180 | 200 | 200 |

Heater | 1.2KW | 2.4KW | 2.4KW | 3KW |

Dimension(WxDxH) | 600x560x430 | 600x560x430 | 540x560x430 | 540x560x430 |

Weight | 45Kg | 45Kg | 65Kg | 77Kg |

Power | 220V50Hz | |||

Air source | Need | Need | ||

Cooling Water | Need | |||

Mold Release | ○ | ○ | ○ | ○ |

Black Resin | ● | ● | ● | ● |

Green Resin | ○ | ○ | ○ | ○ |

Red Resin | ○ | ○ | ○ | ○ |

Conductive Resin | ○ | ○ | ○ | ○ |

Edge-protection Resin | ○ | ○ | ○ | ○ |

Transparent Resin | ○ | ○ | ○ | ○ |

Air filter | ● | ● | ● | ● |

Funnel&Spoon | ● | ● | ● | ● |

Drains | ● | ● | ● | ● |

●Standard○Option

Details

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.