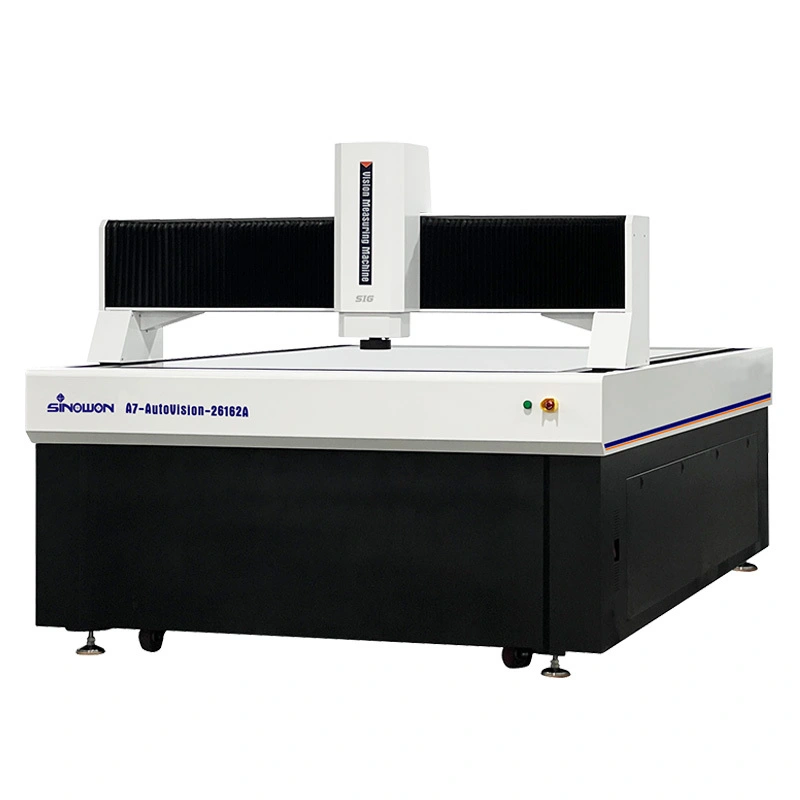

A7-AutoVision26162 Series Super Large Travel Automatic Vision Measuring Machine

A7-AutoVision26162 Series is a Gantry Fully Auto Vision Measuring Machine, it is designed for high accuracy and large dimension measurement. Equipped with movable bridge structure, the workpiece is fixed, which can ensure measurement accuracy and stability. It is widely used in electronic industry, medical devices, LCD, aerospace and other industries measurement.

Product Characteristics

◆ Moving Bridge type structure, measuring workpiece is fixed;

◆ Four-axis CNC fully auto close loop control, auto measurement;

◆ Indian Marble base and pillar, good stability;

◆ Imported RSF linear scale, resolution is 0.1um, grinding ball screw and AC servo motor etc. to ensure the precision and stability of the motion system;

◆ Imported HD color camera to meet the needs of clear observation and accurate measurement;

◆ 8.3x high-resolution motorized coaxial zoom lens, accurate doubling and one times pixel correction only needed;

◆ With programmable surface 5-ring 8-division LED Cold Illumination and contour LED parallel illumination and built-in intelligent light adjustment, it can automatically control the brightness in the 8-division;

◆ Powerful function and easy operation iMeasuring Software to enhance quality control;

◆ Optional MCP Probe and Laser Senser Module. Machines can be customized according to customers’requirements.

Technical Specification

|

Commodity |

High Precision Super Large Travel Automatic Vision Machine |

||

|

Model |

A8-AutoVision-16262 |

||

|

X/Y Axis Travel (mm) |

1600*2600 |

||

|

Z Axis Travel (mm) |

200 |

||

|

X/Y/ZAxis Linear Scale (um) |

Open Grating Ruler, resolution: 0.1um |

||

|

Linear Guide |

X Axis |

260N.m Thrust Magnetic Levitation Motor with INA Germany Dual Linear Guide |

|

|

Y Axis |

1100N.m Thrust Dual Magnetic Levitation Motor with INA Germany Quadruple Linear Guide and Dual Grating Encoder |

||

|

Z Axis |

Panasonic 400W AC Servo Motor with Brake and INA Germany Dual Linear Guide |

||

|

Operation Mode |

Joystick controller, Mouse operation, automatic detection program |

||

|

Accuracy* (um) |

E1x,y |

4.0+L/200(um) |

|

|

E1xy |

5.0+L/200(um) |

||

|

E1z |

5.0+L/200(um) |

||

|

Repeatability (um) |

2um |

||

|

Illumination System |

Contour |

LED parallel contour illumination |

|

|

Surface |

0~255 Stepless adjustable 5-ring 8-division LED surface illumination |

||

|

Video System** |

1/1.8" High-Definition Digital Color Camera |

||

|

8.3X Motorized Zoom Lens; Optical Magnification: 0.6X~5.0X; Video Magnification: 20X~170X (21” monitor) |

|||

|

Measuring Software |

iMeasuring |

||

|

Operating System |

Support WIN10/11-32/64 bit operating system |

||

|

Language |

English, Simplified Chinese, traditional Chinese, other languages can be added |

||

|

Working Environment |

Temperature 20℃±2℃, temperature change<1℃/Hr; humidity 30%~80%RH; vibration<0.02g's, ≤15Hz |

||

|

Power Supply |

AC220V/50Hz; 110V/60Hz |

||

|

Dimension (WxDxH) (mm) |

3572*2170*1926 |

||

|

Net Weight (Kg) |

6500 |

||

Note:

L is measured length(mm), the mechanical accuracy of Z-axis and focus accuracy is greatly related to the surface of the workpiece.

Magnification is approximate value, it is related to the dimension of monitor and resolution.

Field of view(mm) = (diagonal*Horizontal*Vertical)

Product Configuration Model Description(Example with A7-AutoVision-26162):

|

Product Category |

2.5D |

3D |

2.5D |

3D |

|

Commodity |

2.5D Automatic Vision Measuring Machine |

3D Automatic Contact & Vision Measuring Machine |

2.5D Automatic Laser-Scan & Vision Measuring Machine |

3D Automatic Multisensory Measuring Machine |

|

Model |

A8-AutoVision-16262A |

A8-AutoVision-16262B |

A8-AutoVision-16262C |

A8-AutoVision-16262D |

|

Code# |

523-180R |

523-280R |

523-380R |

523-480R |

|

Type |

A |

B |

C |

D |

|

Significance |

Optical Zoom-lens Sensor |

Zoom-lens Sensor and Contact Probe Sensor |

Zoom-lens Sensor and Lazer Sensor |

Zoom-lens Sensor, Contact Probe Sensor and Lazer Sensor |

|

Contact Probe |

Without |

MCP-Kit1 |

Without |

MCP-Kit1 |

|

Lazer Module |

Without |

Without |

Omron Lazer |

Omron Lazer |

|

Software Version |

iMeasuring4.1 |

iMeasuring4.2 |

iMeasuring5.0 |

iMeasuring5.1 |

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2026 Sinowon | All Rights Reserved.