efficient tensile testing machine design for electronic industry

- Sinowon always gives priority to customers. Depending on great sales system, we are committed to providing excellent services covering from pre-sales to in-sales and after-sales.

1. Sinowon automated optical inspection system is made of good-quality materials and beautifully crafted by skilled worker.

2. The product is resistant to flaking. After withstanding a certain sharp temperature change or collision, it will not easily fail.

3. The product is considered to have high market value and has a good market prospect.

4. The product is extensively demanded in the market due to its unmatched advantages.

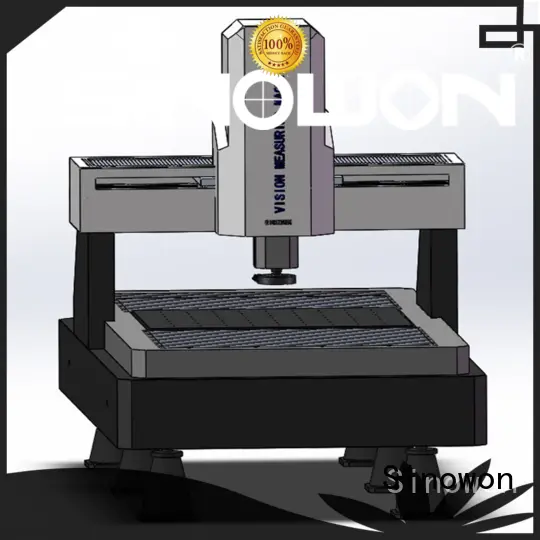

3D Automatic Coordinate Measuring Machine AutoTouch1653P

Requires sampling test product 2D dimension, shape and position tolerance, and automatically output the report.

Test sample size: within 1600*500*300mm

Application: Semiconductor、electronic

Product name | 3D Automatic Vision Coordinate Measuring Machine | |

Model | AutoTouch 1653P | |

Code# | 523-181S | |

X-Y Travel(mm) | 1600x500mm | |

Z Travel(mm) | 300mm | |

X/Y/Z 3-axis Linear Scale mm | GSI Open metal patch scale, Resolution:0.0001mm | |

X/Y/Z Guidance Mode | THK P grade linear guide,Dual rail dual slider guide; Panasonic AC servo closed motor and drive module ; | |

Z-axis probe measuring system (option,customized) | Renishaw MCP-K Probe 3D measuring system 100mm calibration black or 25mmcaliration ball | |

Laser Measuring (option,customized) | Keyence LK-G30A Laser and professional software to achieve flatness and height measurement. (Optional); | |

Operate method | Joystick controller, Mouse operation, automatic detection program | |

Accuracy* | X/Y:≤2.4+L/200(um) | |

Z:≤4+L/200(um) | ||

Repeatability | ±2um | |

Vision System** | 1/2"TEO colorful CCD camera | |

12.5X Automatic Zoom Lens; | ||

Optical Magnification:0.58X-7.5X,Video Magnification:18X~236X | ||

Illumination | Contour | LED Parallel Contour Illumination |

Surface | 5-ring 8-division 0~255 grade continue adjustable | |

Software System | iMeasuring 4.2 Fully Auto Measuring Software | |

Load Capacity | 800Kg | |

Working Environment | Temperature 20℃±2℃ Humidity Range<2℃/hr Humidity 30~80%, Vibration<0.002g,<15Hz | |

Power | 220V/50Hz/10A | |

Dimension | 2360*1100*1750mm | |

Package size | 2600*1250*1880mm | |

Weight | 1680Kg | |

* L is measuring length,unit is mm, the mechanical accuracy of Z-axis and focus accuracy is greatly related to the surface of the workpiece.

**Magnification is approximate value, it is related to the dimension of monitor and resolution.

Customers can choose 0.5X or 2X optional objective, and realize image magnification: 9X~118X or 36X~472X.

FOV(mm)

| Magnification | 0.7x | 1x | 2.0x | 3.0x | 4x | 4.5x |

1/2”CCD | 11.43x9.14x6.86 | 8x6.4x4.8 | 4x3.2x2.4 | 2.67x2.13x 1.6 | 2x1.6x1.2 | 1.78x1.42x 1.07 |

FOV(Field of View)=(Diagonal *Horizontal*Vertical)

Company Features

1. We mainly specialize in scale production of tensile testing machine with the most competitive price.

2. Supported by automated optical inspection system technology, optical measurement enjoys a good reputation for its high quality.

3. Remembering the mission of optical measurement machine is a must in Sinowon. Call now! As a defender for tensile testing machine, Sinowon Innovation Metrology Manufacture Limited. has always insisted on optical inspection tools . Call now!

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.