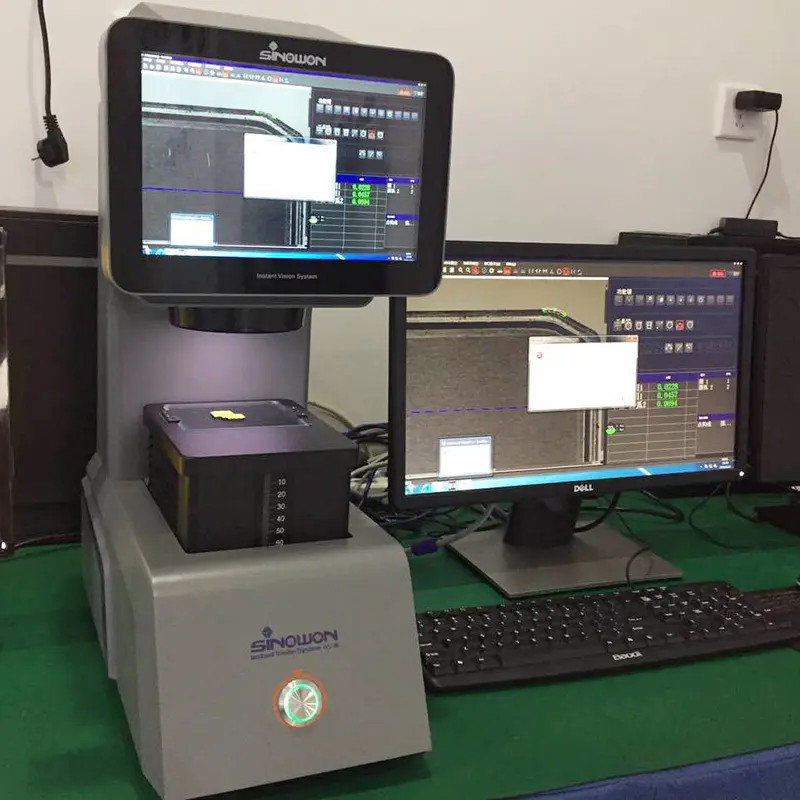

Instant Vision measurement System

- Sinowon runs a comprehensive service system covering from pre-sales to sales and after-sales. Customers can rest assured during the purchase.

1. The quality inspection of Sinowon manual vision measuring machine will be conducted at the final production stage. It will be checked for its smoothness, splicing trace, dirt resistance, anti-yellowing capability, etc.

2. The product is excellent in overall quality and longevity. The framework is constructed with 100% solid wood, which guarantees its weight.

3. The product has received much attention since its launch and is believed to be more successful in the future market.

4. The product finds its application in various industries.

Product Feature

High accuracy and excellent repeatability

◆ High depth of field, low distortion double telecentric lens, no need to repeat focus.

◆ Software processes the image by the way of Sub-pixel edge detection and automatic removal of burrs and outliers and the least-square method to ensure accuracy.

Friendly operation

◆ Automatic location and orientation correction, automatically detect and measure based on the recorded shape of the sample, measure with a click of button.

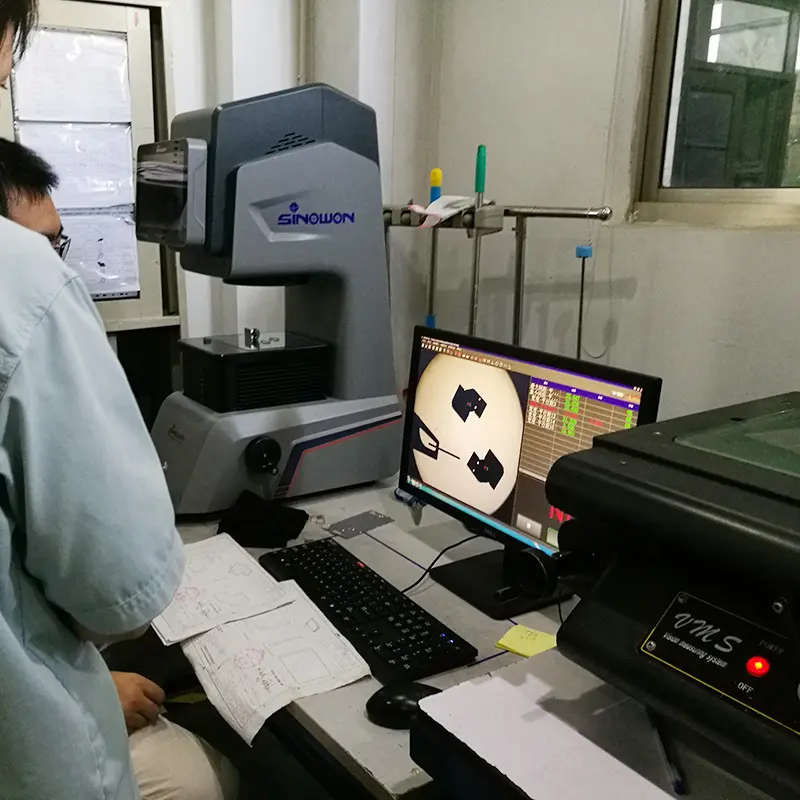

Efficient batch measurement

◆ Automatically identify multiple parts, test elements, then conduct automatic measurement, satisfied with batch measurement requirements.

◆ Entire image, no need to move the working stage, both high efficiency and high accuracy.

◆ Improve efficiency, save labor cost, eliminate operator error.

Quality Control and Statistical Process Control (SPC)

◆ Automatic memory and output measuring values, and make test data simple applied.

Technical Specification

| Model | iVS-30 | iVS-60 | iVS-80 | iVS-160 |

| Code# | 500-030 | 500-060 | 500-080 | 500-160 |

| Lens | 0.3X Double Telecentric Lens | 0.17X Double Telecentric Lens | 0.088X Double Telecentric Lens | 0.088X Double Telecentric Lens |

| Working Distance | 110 mm | 110 mm | 120 mm | 390mm |

| Wide Field | Ø 30mm(28x24) | Ø 60mm(56x50) | Ø116mm(94x76) | Ø229.6mm(146.7x110) |

| Measurement Accuracy | ±2um | ±3um | ±4um | ±7um |

| Repeatability Accuracy | ±1um | ±2um | ±2um | ±5um |

| Camera | 2/3’’ 5 million pixel B/W camera (Ethernet) | |||

| Illumination | Digital controls, automatic memory | |||

| Telecentric Green LED Contour illumination | ||||

| Ring White LED illumination | ||||

| PC System | DELL (I5 Intel processors) | |||

| Monitors | Built-in 10.4 inch LCD Monitor(1920*1080) | |||

| External 21.5 inch LCD Monitor(1920*1080) | ||||

| Measuring Software | iMeasuring 2.0 | |||

| Measuring Amount | Max.99 | |||

| Test Time | <5S (Less than 100 tests) | |||

| Output data | Test data, reports, determine the results (OK, NG, WAIT), etc | |||

| Function | 2D measurements: points, lines, circles, arcs, angles, distance, oval, O-rings, Groove, rectangle, parallelism | |||

| Auxiliary Function | Intersection, parallel, perpendicular, tangent, bisection. | |||

| Geometric Tolerances | Dimension tolerances and position tolerances, tolerances of form and position (Point position concentricity, straightness, parallelism, roundness, straightness, profile, etc) | |||

| Measurement Mode | Manual / Automation | |||

| SPC Data Management and Control | √ | |||

| CAD Data Input / Output | √ | |||

| Power Supply | AC100~240V,50~60Hz | |||

Application

It is widely used in quick batch measurement of precision screws, precision springs, gears, cell phone case, cell phone glass, precision metal parts and other parts in small size.

Product Details

Company Features

1. When it comes to professionalism for manufacturing instant measurement system , Sinowon Innovation Metrology Manufacture Limited. is undoubtedly one of them.

2. The quality control (QC) team contributes a lot in increasing our company's profits. They have a strong sense of responsibility in checking nearly every piece of the product, not letting any unqualified products go. It is their responsibility that attracts more customers to cooperate with us.

3. Sinowon hopes to become an influential company to produce coordinate measuring machine. Get info! Sinowon Innovation Metrology Manufacture Limited. gives our all to protect and build our quality reputation. Get info! The culture of customer first is emphasized in Sinowon. Get info! Sinowon is ambitious and has become one of the most dominant suppliers. Get info!

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.