polishing equipment's qualifications and internationally authoritative certifications

Customers may see the certifications we have got by browsing the home page of our website. Or we can show the electric edition of the data to customers if they request. Since launched, Sinowon Innovation Metrology Manufacture Limited. polishing equipment has been recognized by many national and international authoritative institutions. Having passed the tests of several institutions, our products have won the certifications which are highly recognized by domestic and overseas authorities. Those certifications are proof of our products being high-quality, high-performance, and highly authenticated.

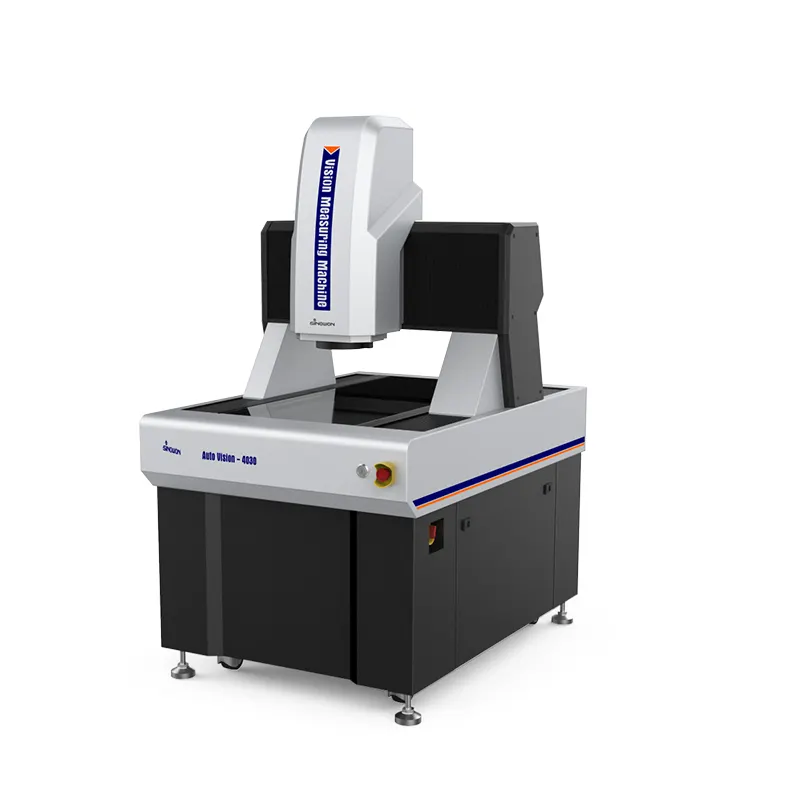

Sinowon is a leading company in Videoscope field in terms of market value. Sinowon's hardness tester series include multiple types. Sinowon horizontal projection profile is engineered with the assistance of computers and various software. They are Computer-Aided Manufacturing (CAM) which includes CNC tool path and rapid prototyping as well as Engineering analysis and simulation which include finite element, fluid flow, dynamic analysis, and motion. The product is well used in many large engineering projects. The quality of this product is improved under international standards. The product is highly praised in many exhibitions such as Shanghai Electronica China Show.

In accordance with our belief that environmental preservation is one of our key social responsibilities, we continually strive to improve environmental performance.

Hydraulic universal testing machines have very high accuracy requirements.

The hydraulic system is the power drive mechanism of the tensile testing machine.

The specific application of the electronic universal testing machine in the automobile manufacturing process: The electronic universal testing machine needs to be used for automobile parts.

Wave soldering refers to the molten solder (lead-tin alloy), sprayed by electric pump or electromagnetic pump into the solder wave required by the design, can also be formed by injecting nitrogen into the solder pool, so that it is pre-loaded The printed board of the component realizes the soft soldering of the mechanical and electrical connection between the solder end or the pin of the component and the pad of the printed board through the solder wave.

The frequency converter is a power control equipment that uses frequency conversion technology and microelectronics technology to control AC motors by changing the frequency of the motor's working power supply.

Electronic universal testing machine is a necessary equipment to control the quality of products.

The calibration operation of the electronic universal testing machine is still relatively unfamiliar to friends who use it for the first time.

Selective wave soldering defects and their prevention.

Testing machine, broadly speaking, is an instrument that verifies the quality or performance of a product or material according to the design requirements before it is put into use.

The tensile force is not an accurate value after being measured by the testing machine, and subsequent calculations are required to get the desired value.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2026 Sinowon | All Rights Reserved.