Sinowon metallographic equipment factory for LCD1

The MC-250 is a tabletop manual wheel feed abrasive cutter with robust and durable design. This is a versatile cutting machine designed for sectioning an extremely wide range of materials, such as ferrous metals, non-ferrous metals, fasteners, foundry castings, heat treated parts, rocks and ceramics, etc. It has large workspace and various clamping vises options. Ideal for material test laboratory, as well as for small industrial or production applications.

Product Feature

◆ Aluminum casting, powder coated

◆ Variable speed motor (option)

◆ T-slot Table made of stainless and aluminum alloy

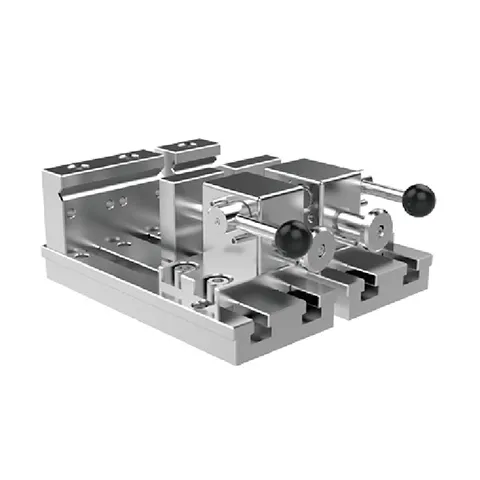

◆ Fast Cam Locking Vises, made of 304 stainless steel

◆ Chamber illumination with LED

◆ Electronic braking system for faster stopping the blade(option)

◆ Side port window for longer samples

◆ Mobile plastic recirculation coolant tank

◆ Large workspace

Specification

| Product Name | Manual Cutting Machine |

| Model | MC-250 |

| Manual/Motor | Manual/Motor |

| Cooling Method | Water-cooling |

| Cutting Disk | 250x32x1.5mm |

| Revolving Speed, rpm | 2850rpm |

| Max cutting ability, mm | 80mm |

| Travel | 200mm |

| Working stage size | 316x260mm |

| Main Machine | 810x750x620mm |

| Power | 2.2KW |

| Power Supply | Three phase380V, single phase220V |

Option Accessories

LED Lamp

Large Workong Space

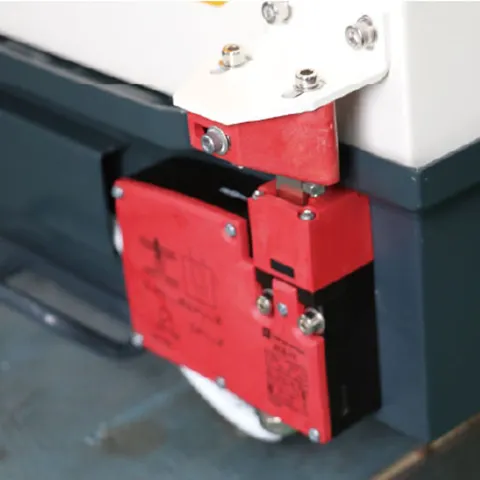

Schneider Switch(Optional)

Vertical Clamp

304 SS Toggle Clamp

ABB Motor(Optional)

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.