Sinowon reliable brinell indenter for steel products

1. The creation of Sinowon brinell indenter involves some advanced technologies. They include mechanical systems technology, automatic control technology, sensing technology, and servo-drive technology.

2. The product stands out for its stable operation. Since it is mainly controlled by microcomputers, it can run stably without any break.

3. Sinowon Innovation Metrology Manufacture Limited. has strong reaction ability and new product development ability in brinell hardness test field.

4. Sinowon is the preferred brand in brinell hardness test industry.

Product Feature

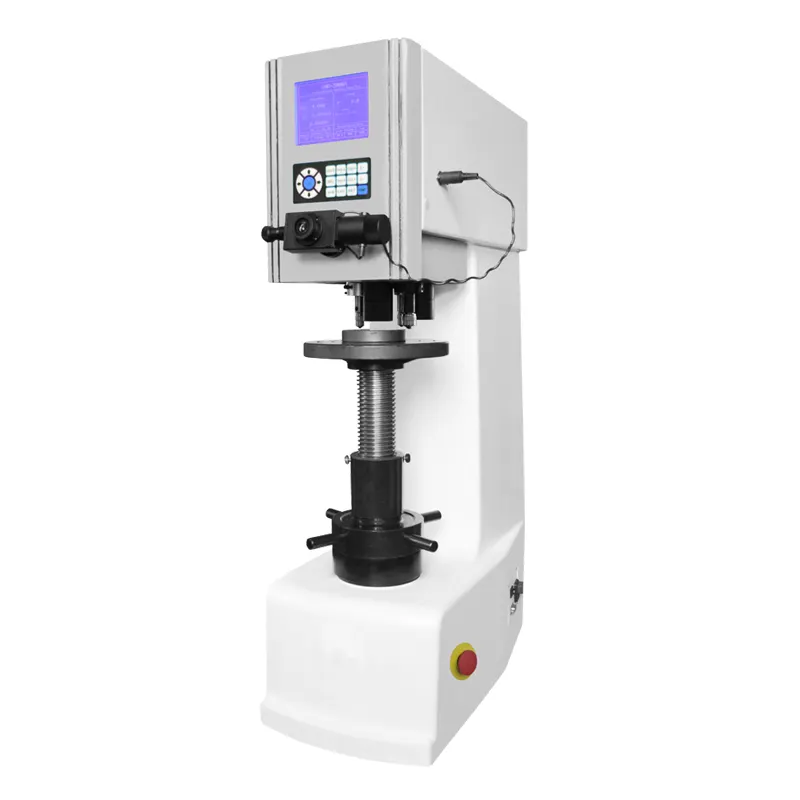

◆ AutoBrin-3000A is the latest generation digital Brinell hardness tester, it equips with motorized turret to install 10mm, 5mm, 2.5mm tungsten carbide ball indenter, 1x and 2x objectives simultaneously, avoid operation error during switch indenter and objectives.

◆ Apply large LCD to display testing parameters and results, indentation can be measured by 10x digital eyepiece, also available to realize hardness conversion among 17 hardness scales.

◆ Loading control by load cell with accuracy at 0.5‰, microchip can make force compensation automatically lost during loading.

◆ Indentation measurement system integrated by 10x digital eyepiece, 1x and 2x objectives, eliminates manually brinell table checking, to realize directly indentation measurement and display hardness result on LCD.

◆ AutoBrin-3000A equips with built-in mini printer, and can transfer data to computer by RS232, to do further analysis by PC software.

◆ Optional accessory for AutoBrin-3000A has Brinell Optical Measuring System BrinScan.

Application

Because of brinell method apply big loading force and generate big indentation, it is suitable to test hardness of coarse-grained metals, like cast iron, non ferrous metal and their alloy, sale of steels, etc.

Soft metals are also available to test, like Aluminium, copper, plumbum, tin, zinc and their alloy, etc.

Specification

| Name | Auto Turret Digital Brinell Hardness Tester | |

| Model | AutoBrin-3000A | |

| Code# | 831-151 | |

| Loading Force | Kgf | 62.5Kgf, 100Kgf, 125Kgf, 187.5Kgf, 250Kgf, 500Kgf, 750Kgf, 1000Kgf, 1500Kgf, 3000Kgf |

| N | 612.9N, 980N, 1226N, 1839N, 2452N, 4900N, 7355N, 9800N, 14700N, 29400N | |

| Hardness Resolution | 0.1HBW | |

| Brinell Range | (8-650) HBW | |

| Hardness Reading | Display on LCD | |

| Indentation Measurement | Magnification 10x/20x, eyepiece 10x and objective 1x, 2x | |

| Data Output | Mini printer/RS232 | |

| Vertical Space | 260mm | |

| Horizontal Space | 150mm | |

| Dimension | 890×535×260mm | |

| Gross/Net Weight | 180Kg/150Kg | |

| Power Supply | AC 220V/110V±5%,50~60 Hz | |

| Conform Standard | GB/T231.2, JJG150, EN-ISO 6506; ASTM E10-12; JIS Z2243 | |

Accuracy | ||

| Hardness Range | Permitted Error | Repeatability |

| HBW≤ 125 | ≤± 3.5% | ≤ 3.5% |

| 125<HBW≤225 | ≤± 2.5% | ≤ 3.0% |

| HBW> 225 | ≤± 2.0% | ≤ 2.5% |

Company Features

1. Sinowon Innovation Metrology Manufacture Limited. is a company specializing in high-end research and development, manufacturing, sales and service of brinell hardness test .

2. Located in a city that is the economic center of China, the factory is very close to the major ports. Hence, the traffic is very convenient so that our goods can be transported very quickly.

3. Sinowon Innovation Metrology Manufacture Limited. strictly considers the needs of customers in brinell hardness testing machine production. Contact us! Sinowon Innovation Metrology Manufacture Limited. is willing to provide clients with professional solutions with customized brinell hardness . Contact us! Sinowon Innovation Metrology Manufacture Limited. is quite professional and faithful to the vision of surpassing clients. Contact us!

Customer from India

Customer from Canada

Customer from Bangladesh

Customer from Bangladesh

Customer from Russia and Germany

Customer from Africa

Jinan Chenda Testing Machine Manufacturing Co., Ltd. was established in 2003, and is a professional comprehensive company which integrates research and development, production, marketing and service. Our products are applied widely in many fields such as scientific institutions, colleges, metallurgical, construction materials, railway trains, highway traffic, rubber plastic, wire and cable, and fire facilities.

Our company is located in the beautiful spring city - Jinan, which is the center for developing testing machines in China as well as the largest testing machines producing base at home.

We are specialized in providing:

1. Hydraulic universal testing machines

2. Electronic universal testing machines

3. Friction and wear testing machines

4. Complete impact testing equipment and bending testing machines

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Copyright © 2025 Sinowon | All Rights Reserved.