What companies are developing Digital Vision Microscopes independently in China?

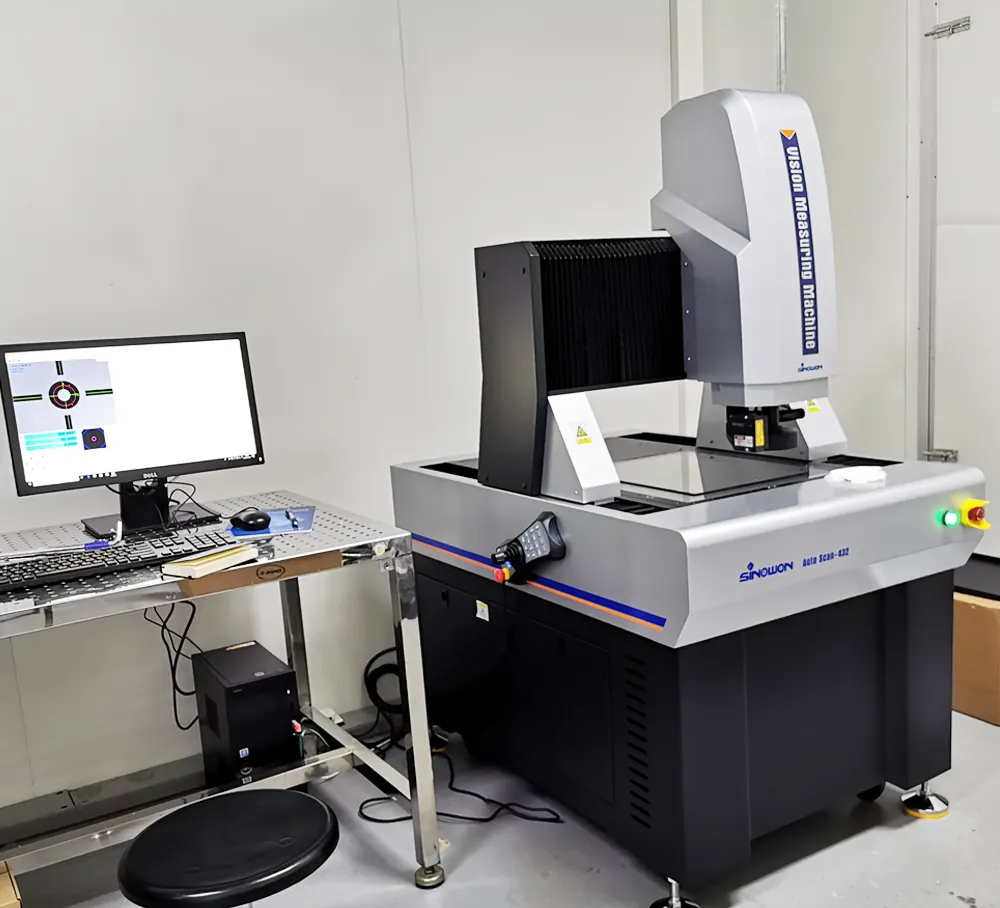

Under the tide of independent research and development, many enterprises choose to follow the science and technology innovation policy guided by the Chinses government. Having studied advanced technology for years, Sinowon Innovation Metrology Manufacture Limited. is also on the list so as to improve the technological content of Digital Vision Microscopes. We not only import brand-new machines and devices from foreign brands but also partner with domestic scientific research institutions and universities to learn the industry-leading knowledge. Our achievements in independent research and development can be regarded as the success of the product in the form of sales volume.

Sinowon, a qualified China-based manufacturer of industrial microscope, has been widely accepted in the international market. manual cmm machine is one of Sinowon's multiple product series. Made from superior materials, profile projector has the advantages of large capacity, high power, low self-discharge rate, good temperature resistance, etc. It can not only support the equipment for a long time, but also can be recycled many times. Sinowon will focus on china microscope, do a good job in Video Microscope industry. The product can be controlled in a motorized way, to eliminate errors caused by manual operation.

With the goal of becoming an excellent metallurgical equipment company, we strives to achieve the biggest value. Check it!

Hydraulic universal testing machines have very high accuracy requirements.

The hydraulic system is the power drive mechanism of the tensile testing machine.

The specific application of the electronic universal testing machine in the automobile manufacturing process: The electronic universal testing machine needs to be used for automobile parts.

Wave soldering refers to the molten solder (lead-tin alloy), sprayed by electric pump or electromagnetic pump into the solder wave required by the design, can also be formed by injecting nitrogen into the solder pool, so that it is pre-loaded The printed board of the component realizes the soft soldering of the mechanical and electrical connection between the solder end or the pin of the component and the pad of the printed board through the solder wave.

The frequency converter is a power control equipment that uses frequency conversion technology and microelectronics technology to control AC motors by changing the frequency of the motor's working power supply.

Electronic universal testing machine is a necessary equipment to control the quality of products.

The calibration operation of the electronic universal testing machine is still relatively unfamiliar to friends who use it for the first time.

Selective wave soldering defects and their prevention.

Testing machine, broadly speaking, is an instrument that verifies the quality or performance of a product or material according to the design requirements before it is put into use.

The tensile force is not an accurate value after being measured by the testing machine, and subsequent calculations are required to get the desired value.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2026 Sinowon | All Rights Reserved.