Vision Measuring Software iMeasuring

Introduction

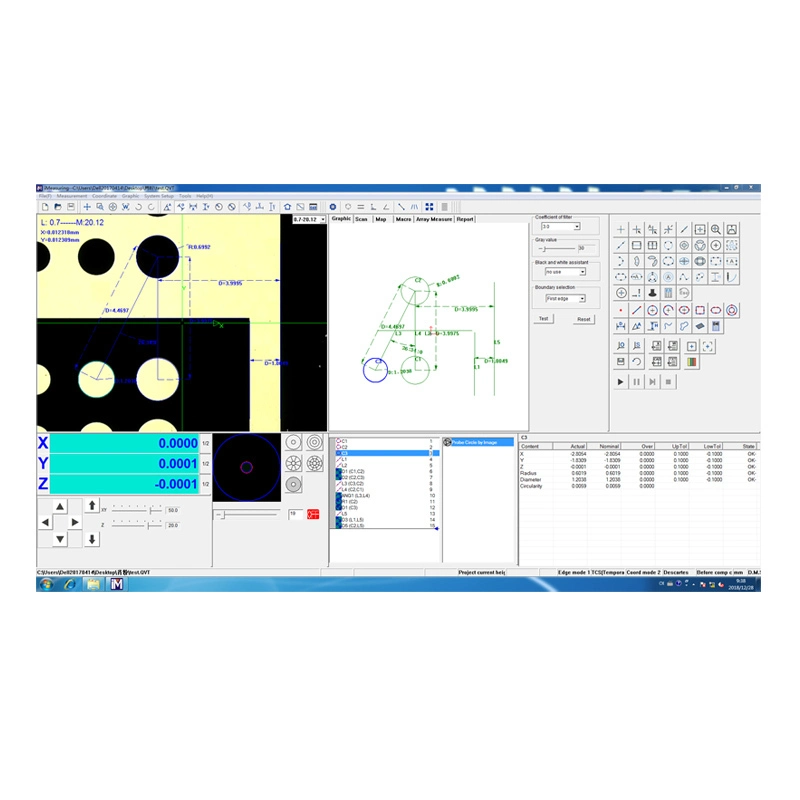

iMeasuring software is a professional multi-sensor measuring software which combined with the developers ten years experience in the measuring and software research industry The design principle is a friendly operation, powerful function, high accuracy and stability, simple maintenance.

Characteristic

l Excellent software architecture design and fully object-oriented, to ensure the software is stable and reliable.

l Support with multiple languages, no need to install a language pack and change the software which is convenient for local customers.

l Professional SPC statistical analysis software connected to measuring software, to realize that the data could automatically export to SPC database without manual operation.

l The same model of software will be permanently free to update, it can help to reduce other trouble to the customer.

l With powerful edge finder algorithm, which can help to get the edge of the shadow or dark image and ensure high accuracy.

l The software could automatically recognize and measure line, circle, arc, and other elements.

l It is based on different elements and supplies multiple element construction functions such as Translation, rotation, extraction, combinations, parallel, vertical, mirroring, symmetry, intersection, tangent, etc.

l The software can show you different intelligent processing functions such as ultra limit red alert, ultra-limit

pause, failure measuring pause, manual measurement, skip running, forced running, etc.

l The measuring data can auto export to TXT, WORD, EXCEL and SPC software database without the third

party software conversion and manual operation.

l The software has breakpoint setting function, it can be intelligent switched between manual measurement and auto measurement.

l The software can import “cancel” and “Recover” to make it easier and faster to operate.

l It can easily measure flatness quickly with powerful laser measuring function, and test the small bumps, pits, V-angle and high-precision surface scanning while video and probe cannot test it.

l The software can supply auxiliary light-dimmer indicated function to avoid measuring error caused by light intensity problem and improve measuring accuracy and efficiency.

l The software can input viewport navigation, to be convenient to position and get a test place by clicking middle key.

l The software can supply many function such as accurate focus, quick focus, image height measurement, and the repeatability can reach to 3um(above 2x magnification ).

l The software can easily and quickly import and export DXF file and set up coordinate system for auto measurement.

l The software supply multiple running control mode, which make it faster and convenient to position.1.Operate handle; 2. Click middle key in the image window, long-press right key; 3. Click middle key in the drawing window; 4. Move element list window to the primitive; 5. Click the mouse in the running control window; 6. Click middle key in the scan window; 7. Click middle key in the map window; 8. Input coordinate value.

l The image window and drawing window can display the measured elements and marking 2D dimension, which get the result directly.

l The software supply multiple system error correction function, such as: Linear compensation, sector compensation, vertical error compensation, Z axis linear error compensation, lens center offset error

compensation, to ensure accuracy can reach to 0.002mm any place in the XY area.

l The software can photograph mosaic the work piece to get a large map, then marke and measure it.

l The software can support to add simple probe based on the video measurement, to realize 3D measurement.

l The software can auto calculate and mark the present magnification and video magnification, and display the pixel measurement value.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.