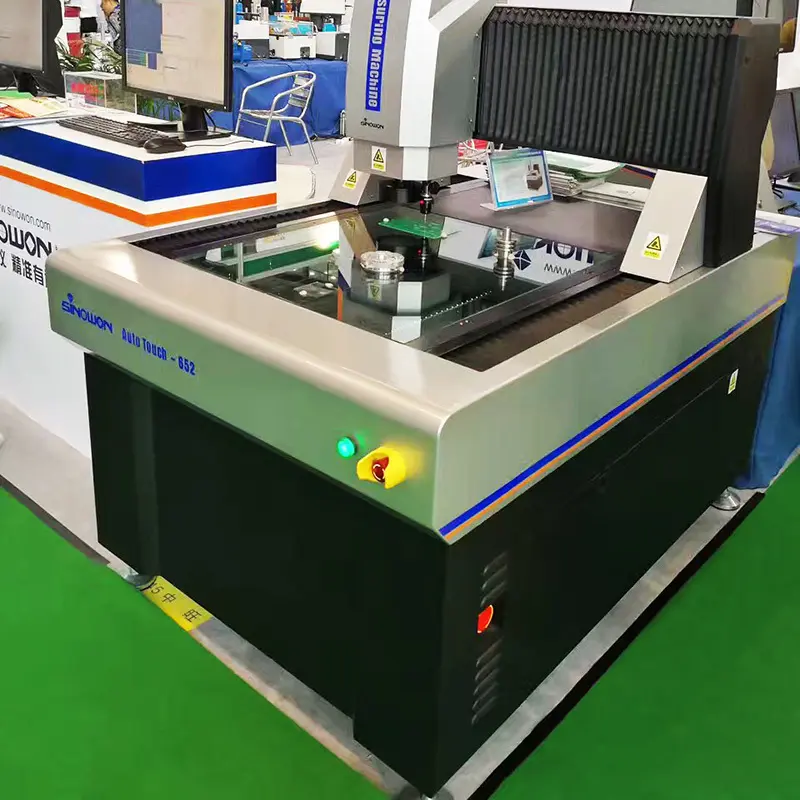

Sinowon vision measurement from China for precision industry

AutoScan is equipped with non-contact laser sensor to realize 3D measurement. It is widely used in non-contact measurement, and able to realize thickness, flatness and scan measurement.

Product Characteristics

◆ Moving bridge structure, measurement workpiece is fixed;

◆ Four-axis CNC fully auto close loop control, auto measurement;

◆ Marble base and pillar, stable and reliable;

◆ Imported open type linear scale, resolution is 0.1um, high accuracy, great stability;

◆ Imported P grade linear guide,, precision grinding ball screw and AC servo motor, ensure accuracy stability of system position;

◆ Imported high definition color industry camera, ensure clear observation and stable measurement requirement;

◆ 6.5X continue auto zoom lens, precision auto zoom, only need to make pixel calibration once time;

◆ Programmable 5-ring 8-division LED surface illumination, contour parallel LED illumination, can realize 256 grade brightness adjustment intelligently;

◆ With imported non-contact laser sensor, realize thickness and flatness and other measurement;

◆ With proprietary fully auto measuring software iMeasuring 5.0, powerful function, simple operation;

◆ Optional touch probe, coaxial illumination and other accessory, it can also be customized according to customer request;

Technical Specification

Commodity | 2.5D Automatic Vision Laser-scanning Measuring Machine | |||||||||

Model | AutoScan 432 | AutoScan 542 | AutoScan 652 | AutoScan 862 | ||||||

Code# | 522-121 | 522-131 | 522-141 | 522-151 | ||||||

X/Y-axis Travel(mm) | 400x300mm | 500x400mm | 600x500mm | 800x600mm | ||||||

Z-axis Travel(mm) | 200mm | |||||||||

X/Y/Z 3-axis Linear Scale(mm) | High precision linear scale,resolution:0.1um | |||||||||

Guidance Mode | Precision linear guide,double-track double slider guide | |||||||||

Operation Mode | Joystick controller, Mouse operation, automatic detection program | |||||||||

Measurement Accuracy | XY-axis:≤1.8+L/200(um) | |||||||||

Z-axis:≤5+L/200(um) | ||||||||||

Repeatability | ±2um | |||||||||

Video System | High definition 1/3" Color CCD Camera | |||||||||

6.5X Automatic Zoom Lens; Optical Magnification: 0.7X~4.5X, Video Magnification: 20X~129X(21.5”monitor) | ||||||||||

Field of View(mm) (Diagonal *Horizontal*Vertical) | Lens Magnification | 0.7x | 1x | 2.0x | 3.0x | 4x | 4.5x | |||

1/3"CCD | 11.43x9.14x6.86 | 8.00x6.40x4.80 | 4.00x3.20x2.40 | 2.67x2.13x1.60 | 2.00x1.60x1.20 | 1.78x1.42x1.07 | ||||

Illumination | Contour | LED Parallel Contour Illumination | ||||||||

Surface | 5-ring 8-division 0~255 grade continue adjustable | |||||||||

Software System | diMeasuring 5.0 Fully Auto Measuring Software | |||||||||

Load Capacity | 30Kg | 30Kg | 30Kg | 30Kg | ||||||

Working Environment | Temperature 20℃±2℃,Humidity Range<2℃/hr,Humidity 30~80%,Vibration<0.002g,<15Hz | |||||||||

Power | 220V/50Hz/10A | |||||||||

Dimension | 1160x800x1650mm | 1450x950x1650mm | 1600x1050x1650mm | 2000x1200x1650mm | ||||||

Packing Dimension | 1380x1170x1910mm | 1690x1300x2000mm | 1800x1400x2000mm | 2300x1700x2000mm | ||||||

Weight(Kg) | 650Kg | 780Kg | 1380Kg | 2000Kg | ||||||

Product Details

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2025 Sinowon | All Rights Reserved.