camera measurement systems instant for gears Sinowon

1. Sinowon camera measurement systems is produced with mature technology in the inflatable item industry. For instance, air-tight technology is applied in its production to make sure tight steam and reinforcement at the joint parts.

2. The functionality of the product is ensured by an expert development team.

3. The product has a long-lasting performance and stable functionality.

4. 'The product is so light and easy to move, the rooms can be reconfigured quickly with very little effort', said one of the hotel owners.

Product Feature

High accuracy and excellent repeatability

◆ High depth of field, low distortion double telecentric lens, no need to repeat focus.

◆ Software processes the image by the way of Sub-pixel edge detection and automatic removal of burrs and outliers and the least-square method to ensure accuracy.

Friendly operation

◆ Automatic location and orientation correction, automatically detect and measure based on the recorded shape of the sample, measure with a click of button.

Efficient batch measurement

◆ Automatically identify multiple parts, test elements, then conduct automatic measurement, satisfied with batch measurement requirements.

◆ Entire image, no need to move the working stage, both high efficiency and high accuracy.

◆ Improve efficiency, save labor cost, eliminate operator error.

Quality Control and Statistical Process Control (SPC)

◆ Automatic memory and output measuring values, and make test data simple applied.

Technical Specification

| Model | iVS-30 | iVS-60 | iVS-80 | iVS-160 |

| Code# | 500-030 | 500-060 | 500-080 | 500-160 |

| Lens | 0.3X Double Telecentric Lens | 0.17X Double Telecentric Lens | 0.088X Double Telecentric Lens | 0.088X Double Telecentric Lens |

| Working Distance | 110 mm | 110 mm | 120 mm | 390mm |

| Wide Field | Ø 30mm(28x24) | Ø 60mm(56x50) | Ø116mm(94x76) | Ø229.6mm(146.7x110) |

| Measurement Accuracy | ±2um | ±3um | ±4um | ±7um |

| Repeatability Accuracy | ±1um | ±2um | ±2um | ±5um |

| Camera | 2/3’’ 5 million pixel B/W camera (Ethernet) | |||

| Illumination | Digital controls, automatic memory | |||

| Telecentric Green LED Contour illumination | ||||

| Ring White LED illumination | ||||

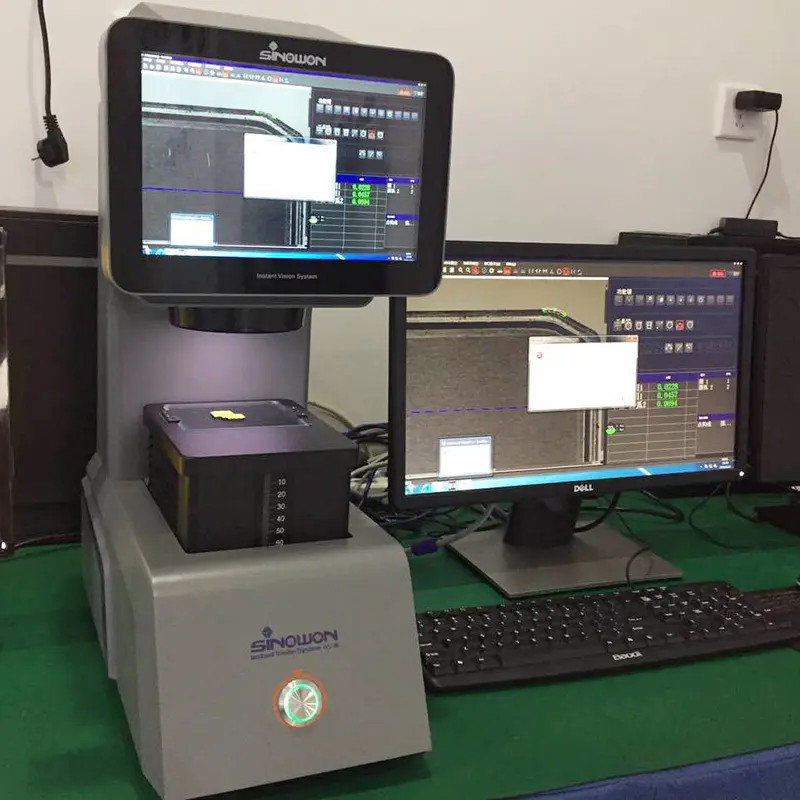

| PC System | DELL (I5 Intel processors) | |||

| Monitors | Built-in 10.4 inch LCD Monitor(1920*1080) | |||

| External 21.5 inch LCD Monitor(1920*1080) | ||||

| Measuring Software | iMeasuring 2.0 | |||

| Measuring Amount | Max.99 | |||

| Test Time | <5S (Less than 100 tests) | |||

| Output data | Test data, reports, determine the results (OK, NG, WAIT), etc | |||

| Function | 2D measurements: points, lines, circles, arcs, angles, distance, oval, O-rings, Groove, rectangle, parallelism | |||

| Auxiliary Function | Intersection, parallel, perpendicular, tangent, bisection. | |||

| Geometric Tolerances | Dimension tolerances and position tolerances, tolerances of form and position (Point position concentricity, straightness, parallelism, roundness, straightness, profile, etc) | |||

| Measurement Mode | Manual / Automation | |||

| SPC Data Management and Control | √ | |||

| CAD Data Input / Output | √ | |||

| Power Supply | AC100~240V,50~60Hz | |||

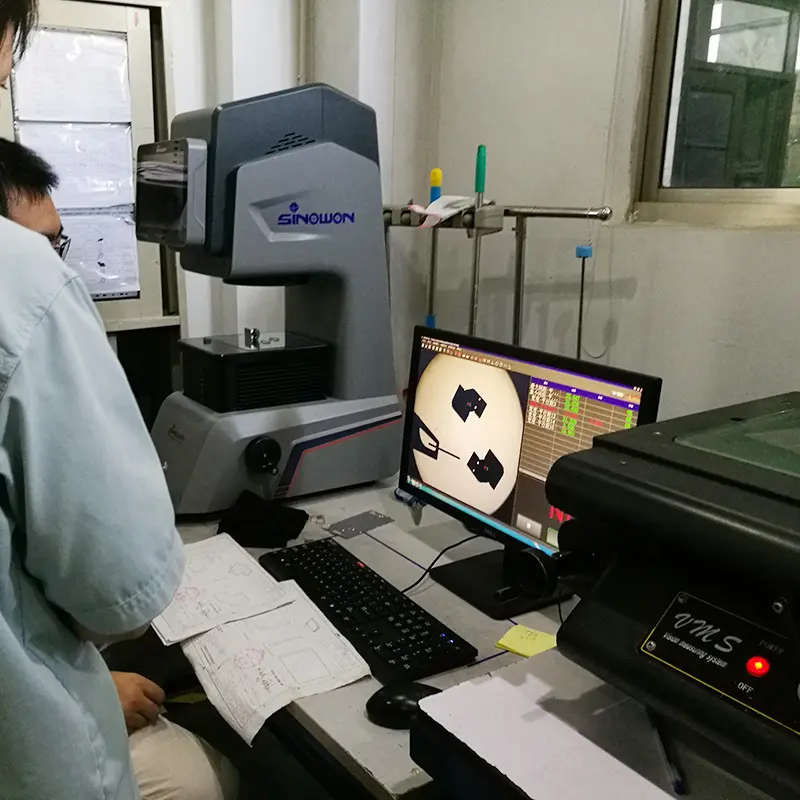

Application

It is widely used in quick batch measurement of precision screws, precision springs, gears, cell phone case, cell phone glass, precision metal parts and other parts in small size.

Product Details

Company Features

1. Sinowon Innovation Metrology Manufacture Limited. has built the global network for R&D, production, and sales of camera measurement systems not only in China but also across the world.

2. It is urgent for Sinowon to develop the innovation of manufacturing coordinate measuring machine technology.

3. Sinowon Metrology Instrument continues to grow to meet the rapidly changing customer needs. Please contact. We expect that Sinowon brand will precede more than many businesses to direct the instant measurement system marketplace. Please contact. Sinowon Innovation Metrology Manufacture Limited. aims to create a new brand of coordinate measuring machine, creating a new market space. Please contact. Sinowon Innovation Metrology Manufacture Limited. sticks to the great dream of leading the development of coordinate measuring machine industry. Please contact.

![]() Tel: 0086-0769-2318 4144

Tel: 0086-0769-2318 4144

![]() Mobile: 0086-137 2828 8444

Mobile: 0086-137 2828 8444

Telephone: 0086-0769-23184144

E-Mail: mz@sinowon.com

Website: www.sinowon.com

Headquarter Address:

C1-508, Tian'an Cyber Park, #1 Glod Road, Nancheng, Dongguan, China (Post Code:523080)

Factory:

Unit 01, Building 7, No. 120, Liantang Road, Tangxia Town, Pengjiang District, Jiangmen, Guangdong, China (Post Code:529000)

International Trade Sector:

C1-501, Tianan, Gloden Road, Nancheng, Dongguan, Guangdong, China(Post Code:523080)

Copyright © 2026 Sinowon | All Rights Reserved.